8

Installation (Cont’d)

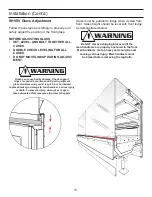

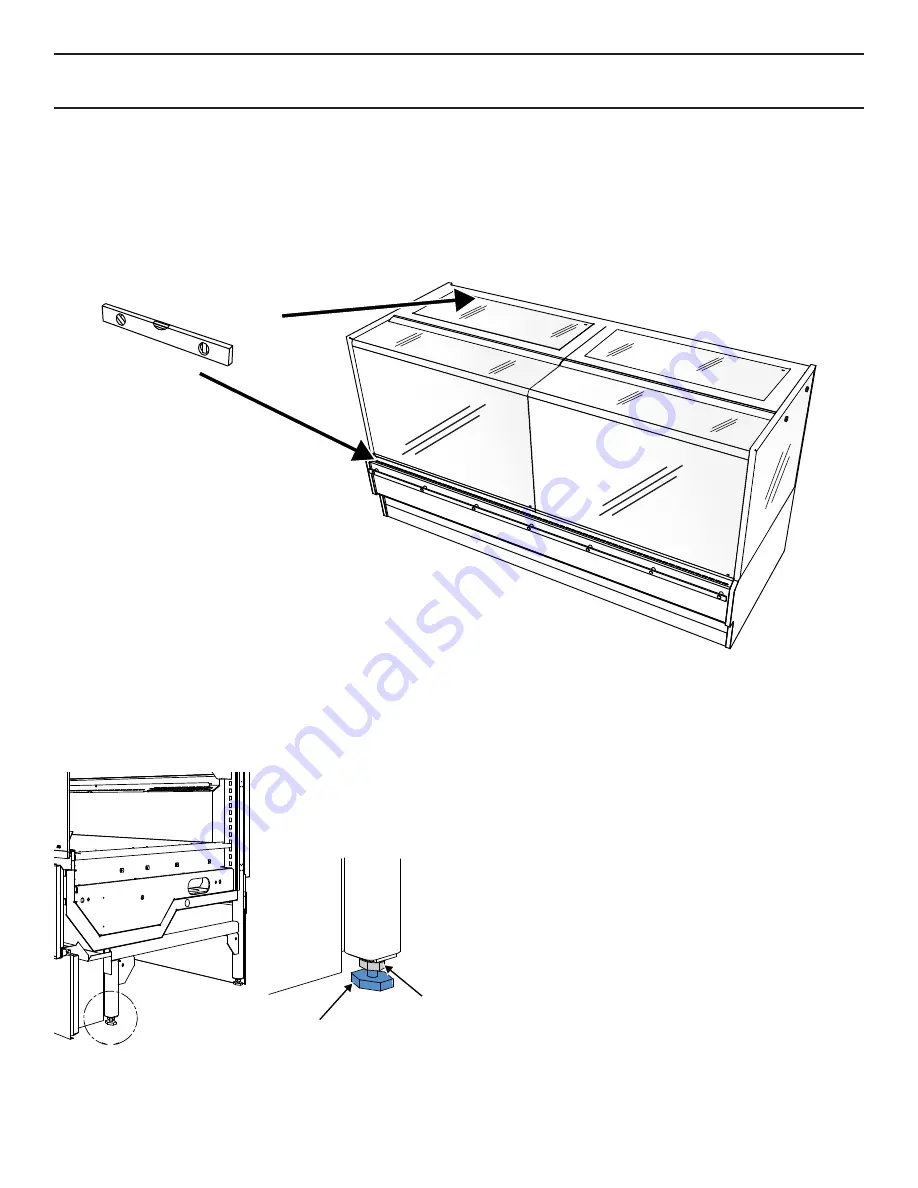

Level Case

Position the case at the highest point. Set a long

magnetized level (4ft [1220 mm] or more) on

either underneath the deck or on top of the case.

Ensure to level case from front to back and side

to side.

Level

(4 ft[1220mm])

Leg Adjustment

Adjust the legs at each corner of the case to

level out any discrepancies in order to optimize

case performance and proper drainage.

A

Levelling Bolt

Lock Nut

Note:

To avoid removing concrete fl ooring, begin

line up levelling from the highest point of the

store fl oor.

A wrench or pliers may be used to adjust each

base leg.

• Loosen the lock nut.

• Turn the levelling bolt to raise or lower the

height of the case as necessary.

• Tighten Lock Nut to set Levelling Bolt in

place.

Summary of Contents for SHVSV Series

Page 9: ...9 Joint Trim Pack list ...

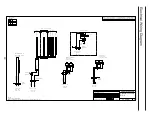

Page 20: ...20 Electrical Wiring Diagram 0 0 0 1 0 0 0 0 2 0 0 3 0 0 1 1 1 1 1 ...

Page 21: ...21 Electrical Wiring Diagram Cont d 0 1 1 1 2 0 1 1 0 1 1 3 0 1 1 4 0 1 1 2 2 2 2 ...

Page 24: ...24 0 1 1 1 2 0 1 1 0 1 1 2 3 0 1 1 4 0 1 1 2 2 2 2 2 2 2 2 Electrical Wiring Diagram Cont d ...