Rev.0208

7

Electrical

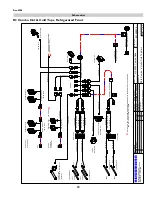

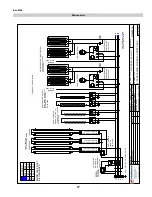

WIRING COLOR CODE

REFRIGERATED

G R E E N

G RO U N D

P U R P L E

A N T I - S W E AT

O R A N G E

L I G H T S

Y E L L OW

R E C E P TA C L E

R E D / B L A C K

T- S TAT / S O L E N O I D 230V

BLACK / WHITE

T- S TAT / S O L E N O I D 115V

B ROW N

FAN MOTORS

HOT

L1

BLACK

L2

ORANGE

L3

BLUE

NEUTRAL

WHITE

NOTE: High Leg Connection

Orange Only

CASE MUST BE GROUNDED

NOTE: Refer to label affixed to case to determine the actual

configuration as checked in the “TYPE INSTALLED” boxes.

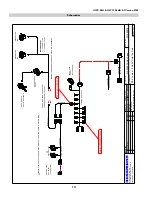

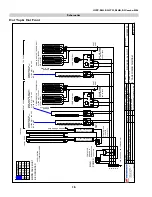

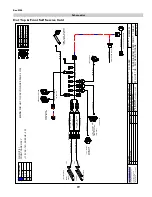

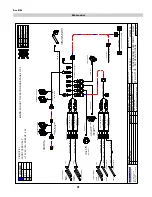

ELECTRICAL CIRCUIT IDENTIFICATION

Standard lighting for all refrigerated models will be full

length fluorescent lamps located within the case at the

top.

The switch controlling the lights, the plug provided for

digital scale, and the thermometer are located at the rear

of the case mullion.

The receptacle that is provided on the exterior back of

these models is intended for computerized scales with a

five amp maximum load, not for large motors or other

high wattage appliances. It should be wired to a dedicated

circuit.

ELECTRICAL SERVICE RECEPTACLES

(When Applicable)

The receptacles located on the exterior of the merchan-

diser are intended for scales and lighted displays. They

are not intended nor suitable for large motors or other

external appliances.

BEFORE

SERVICING

Always Disconnect Electrical

Power at the Main Disconnect

when servicing or replacing

any electrical component.

This includes (but not limited to) Fans,

Heaters, Thermostats, and Lights.

FIELD WIRING & SERIAL PLATE AMPERAGE

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specified. Field wiring from the refrigeration

control panel to the merchandisers is required for refrig-

eration thermostats. Most component amperes are listed

in the “Case Specs” section, but always check the serial

plate.

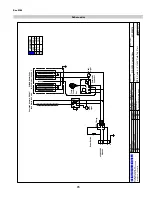

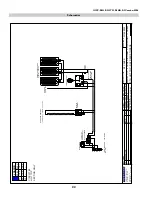

Ballasts are located within the access panel that runs the

length of the rear of the case. Refer to diagram below.

Windex

®

or Glass Plus

®

are the only solutions recom-

mended to be used to clean the non-glare glass. The dam-

age to the glass from improper, caustic solutions is irrepa-

rable.

In addition to cleaning the glass with the recommended

product, there are precautions that should be taken when

working and cleaning the inside of the case.

• When cleaning the inside of the cases, we recom-

mend that the glass be fully opened and covered to

prevent solutions from splashing onto the glass and

ruining the coating on the inside.

PLEXIGLASS & ACRYLIC CARE

Improper cleaning not only accelerates the cleaning cycle

but also degrades the quality of this surface. Normal daily

buffing motions can generated static cling attracting dust

to the surface. Incorrect cleaning agents or cleaning cloths

can cause micro scratching of the surface, causing the plastic

to haze over time.

CLEANING

Hussmann recommends using a clean damp chamois, or a

paper towel marked as dust and abrasive free with

210

®

Plastic Cleaner and Polish

available by calling Sumner

Labs at

1-800-542-8656

. Hard, rough cloths or paper tow-

els will scratch the acrylic and should not be used.

ANTISTATIC COATINGS

The

210

®

has proven to be very effective in not only clean-

ing and polishing the Plexiglass surface, but also providing

antistatic and anti-fog capabilities. This product also seals

pores and provides a protective coating.

CLEANING

PRECAUTIONS

WHEN CLEANING:

Never Use a Cleaning or Sanitizing

Solution that has an OIL BASE

(these will dissolve the butyl

sealants) or AMMONIA BASE (this

will corrode the copper components

of the case)

TO PRESERVE THE ATTRACTIVE FINISH:

Do Use Water and a Mild Detergent for

the Exterior Only!

Do Not Use Abrasives or Steel Wool

Scouring Pads (these will mar the finish)