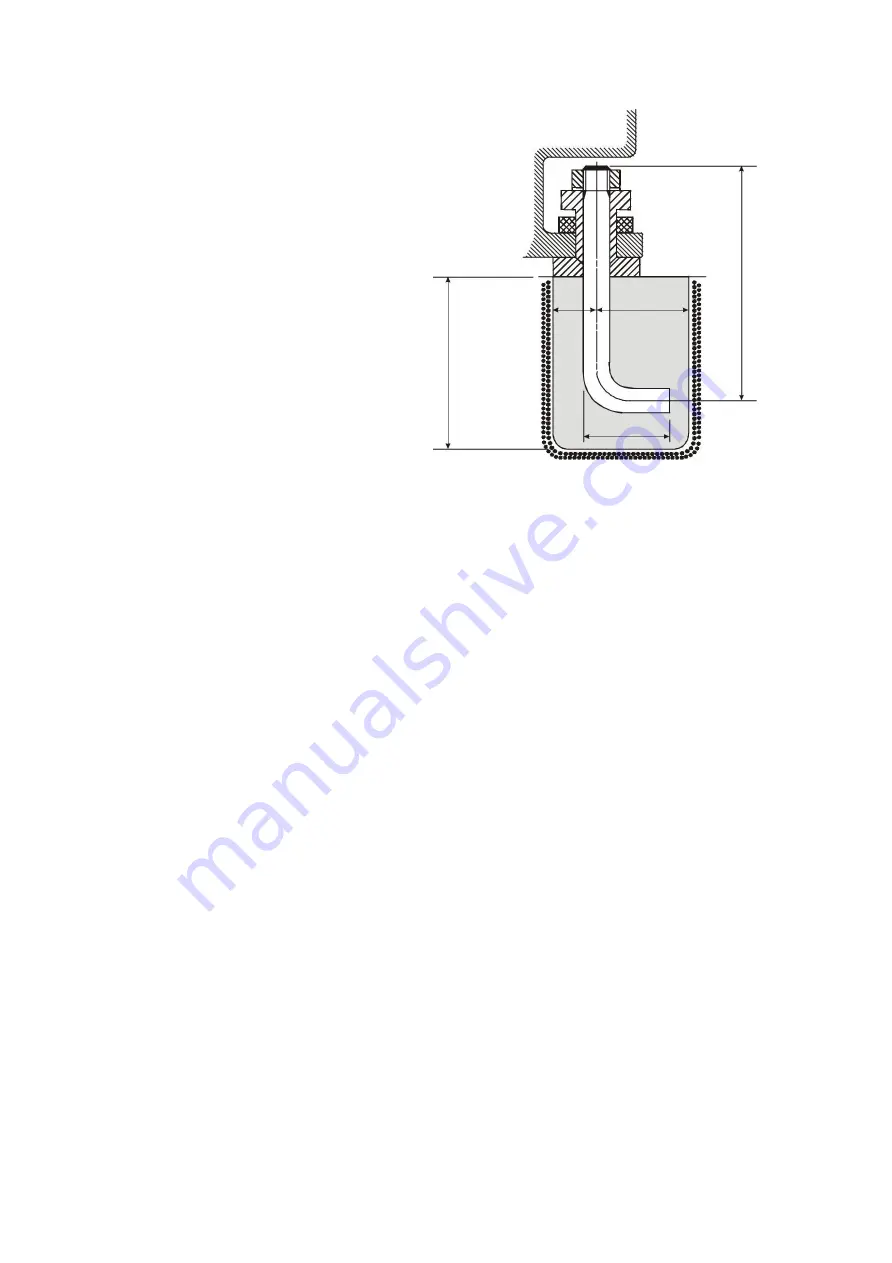

2-3

Basic Foundation

With today’s common use of

tungsten carbide cutting tools,

heavy cutting practices and higher

spindle speeds, a good machine

foundation is a must to avoid

vibration, Please refer to figure 2-

3 for recommended foundation.

300

35

95

2

5

0

65

UNIT-mm

Fig2-3

2-4

Cleaning

Before shipping, the machine is protected with a special anti-rust agent. Before

operating the machine, this agent must be removed. This can be done using a

soft brush/cloth soaked with cleaning solvent or kerosene. To avoid the danger

of fire or explosion, do

NOT

use gasoline or cellulose solvent. After the anti-rust

agent is removed, the machine should be properly lubricated and all moving

parts be checked for proper operation.

2-5

Leveling

Once the machine is on its foundation it is time for leveling. A machinist level

(accuracy 0.02mm/1000mm) should be used. Place level on bed to level machine

for longitudinal and transverse leveling. Tighten foundation bolts, and recheck.

If not level, loosen foundation bolts and re-level machine.

Tolerance should be within

0.04mm/1000mm. (See Figure 2-5)

7

Summary of Contents for HU 480 X 2200 VAC TOPLINE

Page 1: ...L A T H E MODEL HU 480 X 2200 VAC TOPLINE...

Page 5: ...1 INVERTER TRANSMISSION LATHE 1 1 Machine Assembly 4...

Page 33: ...7 4 Lubrication Location A Oil input hole B Oil drain hole 32...

Page 37: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 75: ...HU 480 x 2200 VAC TOPLINE...

Page 76: ......