21

7. Turn on furnace power supply.

GAS INPUT RATE INFORMATION

See furnace rating plate for input rate. The input rate for natural

gas is determined by manifold pressure and orifice size.

Determine natural gas orifice size and manifold pressures for

correct input at installed altitude by using Table 5 or 6.

NOTE

: All models in all positions except Low NOx models in

downflow and horizontal positions use Table 5 (22,000 Btuh per

burner). Low NOx models in downflow or horizontal positions

must use Table 6 (21,000 Btuh per burner). See input listed on

rating plate.

1. Obtain yearly heat--value average (at installed altitude) for

local gas supply.

2. Obtain yearly specific--gravity average for local gas sup-

ply.

3. Find installation altitude in Table 5 or 6.

NOTE

: For Canada altitudes of 2000 to 4500 ft., use U.S.A.

Altitudes of 2001 to 3000 ft. In Table 5 or 6.

4. Find closest natural gas heat value and specific gravity in

Table 5 or 6.

5. Follow heat--value line and specific--gravity line to point

of intersection to find orifice size and high-- and low--heat

manifold pressure settings.

Furnace gas input rate on rating plate is for installations at

altitudes up to 2000 ft. (610 M).

In the U.S.A

.; the input rating for altitudes above 2000 ft.

(610M) must be reduced by 4 percent for each 1000 ft. (305 M)

above sea level.

In Canada

; the input rating must be derated by 5 percent for

altitudes of 2000 ft. (610 M) to 4500 ft. (1372 M) above sea

level.

The Conversion Kit Rating Plate accounts for high altitude

derate.

SET GAS INPUT RATE

1. Make sure the gas supply is turned off to the furnace and

at the electric switch on the gas valve.

2. Remove the 1/8--in. NPT plug from the outlet pressure tap

on the gas valve.

3. Connect a manometer to the outlet pressure tap on gas

valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Verify SW1-2 (LHT) on furnace control is turned “ON”.

8. Jumper R and W/W1 thermostat connections to call for

heat.

9. Check manifold orifices for gas leaks when main burners

ignite.

10. Adjust gas manifold pressure. Refer to Table 5 or 6.

11. Remove caps that conceal adjustment screws for gas valve

regulators.

12. Adjust low--heat input rate manifold pressure for natural

gas.

13. Turn low--heat adjusting screw counterclockwise (out) to

decrease input rate or clockwise (in) to increase input rate.

NOTE

: When correct input is obtained, main burner flame

should be clear blue, almost transparent (See Fig. 12).

14. Jumper R, W/W1 and W2 on control center thermostat

connections. This keeps furnace locked in high--heat oper-

ation.

15. Adjust high--heat input rate manifold pressure for natural

gas.

16. Turn high--heat adjusting screw counterclockwise (out) to

decrease input rate or clockwise (in) to increase input rate.

17. Replace caps that conceal gas valve regulator adjustment

screws.

NOTE

: When correct input is obtained, main burner flame

should be clear blue, almost transparent (See Fig. 12).

18. Remove jumper across R, W1, and W2 after high--heat ad-

justment to terminate call for heat.

19. Turn setup switch SW1-2 (LHT) on furnace control to

OFF position.

20. Turn furnace gas valve switch to OFF position.

21. Turn off furnace power supply.

22. Remove manometer and re-install manifold pressure tap

plug.

23. Turn furnace gas valve switch to ON position.

24. Turn on furnace power supply.

25. Set room thermostat to call for heat.

26. Check pressure tap plug for gas leaks when main burners

ignite.

27. Check for correct burner flame.

28. After making the required manifold pressure adjustments,

check and adjust the furnace temperature rise per the fur-

nace installation instructions.

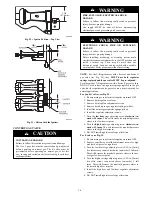

LABEL APPLICATION

1. Fill in Conversion Responsibility Label 338304--205 and

apply to Blower Access Door of furnace as shown. Date,

name, and address of organization making this conversion

are required. See Fig. 28.

2. Attach Conversion Rating Plate Label 338304--204 to

Outer Door of furnace. See Fig. 29.

3. Apply Gas Control Conversion Label:

a. For 2--stage J and G gas valves, use Gas Control Conver-

sion Label 338304--202. (DO NOT use 338304--203,

which is similar.)

b. For 2--stage E gas valve, use Gas Control Adjustment La-

bel 338304--203. (DO NOT use 338304--202, which is

similar.)

CHECKOUT

1. Observe unit operation through two complete heating

cycles.

2. See Sequence of Operation operation in furnace Installa-

tion, Start--Up, and Operating Instructions.

3. Set room thermostat to desired temperature.