Page 14 of 20 pages

Storage of wood

A moisture content of 12-18% is achieved by storing recently felled wood outdoors under a lean-to

for at least one year, preferably 2 years. Wood stored indoors has a tendency to become too dry and

combust too quickly. However, it might be advantageous to store fuel for lighting a fire indoors for a few

days prior to use.

We recommend that you buy a moisture meter to continuously check that the wood has the correct

moisture content before it is used for firing. Split the wood and measure the moisture content of the

split surfaces.

Recommended dimensions

The dimensions of the fuel are important to good combustion. The dimensions should be as follows:

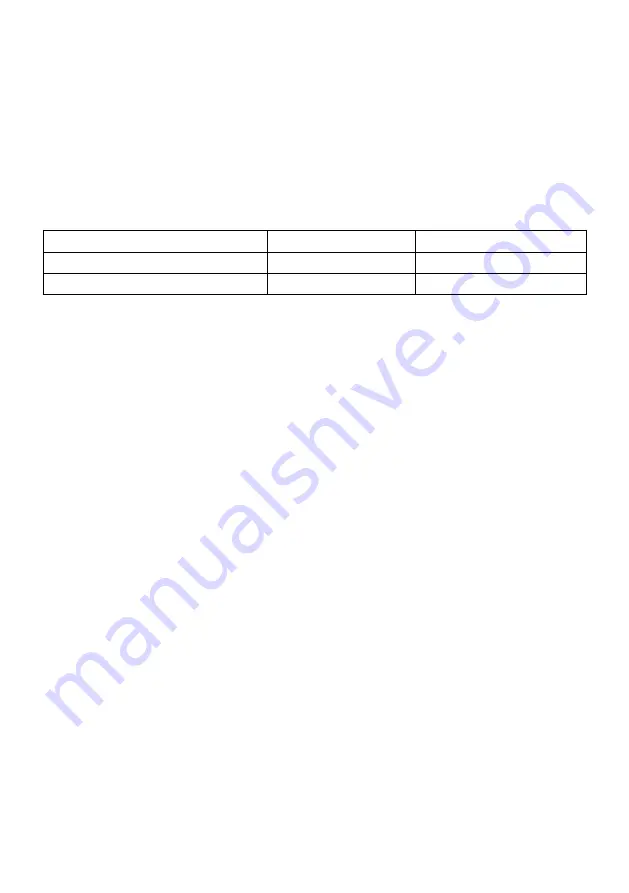

Fuel type

Length in cm

Diameter in cm

Wood for kindling a fire (finely chopped)

25

2-5

Chopped wood

25

5-8

Special fire lighting guide for stoves with soapstone or natural stone cladding

Stones are natural products which need to adjust to temperature changes. We recommend following

the procedure below:

1. First stoking (drawing F)

Push the air control lever (1) all the way to the right push the shaking grate lever (2) all the way in. Place

2 pieces of wood (5-8 cm in diameter) horizontally in the bottom of the combustion compartment (cor-

responding to 1-2 kg). Place 5-8 pieces of kindling randomly on top. Place 2 firelighters between the top

layer of kindling. Light up the firelighters and close the stove door. If condensation forms on the glass,

keep the door ajar for a little while and close again. When the fire has gone out, open the door and leave

it open while the stove cools to room temperature.

2. Second stoking

Push the air control lever (1) all the way to the right push the shaking grate lever (2) all the way in. Place

2 pieces of wood (5-8 cm in diameter) horizontally in the bottom of the combustion compartment (cor-

responding to 1-2 kg). Place 5-8 pieces of kindling randomly on top. Place 2 firelighters between the top

layer of kindling. Light up the firelighters and close the stove door. If condensation forms on the glass,

keep the door ajar for a little while and close again.

When no more yellow flames are visible and a suitable layer of embers has built up, the stove can be

stoked again. There is a suitable layer of embers when the bottom of the stove is covered completely.

Half fill the combustion chamber with dry wood with a diameter of about 7-9 cm. When all of the wood

has caught fire, turn the regulator (1) to middle position. Allow the fire to burn and let the stove cool to

room temperature before stoking again.

3. Third stoking

Repeat the procedure for the second stoking, Allow the fire to burn and let the stove cool to room

temperature after the fire has gone out.

Restoking:

Follow the general instructions, see the sections “Lighting the stove” and “Stoking”.

Lighting the stove (drawing F)

A successful combustion process requires that the wood is lit in the right way. A cold stove and a cold

chimney challenge the combustion process. It is important to achieve a high flue gas temperature quickly.

Push the air control lever (1) all the way to the right push the shaking grate lever (2) all the way in. Place

2 pieces of wood (5-8 cm in diameter) horizontally in the bottom of the combustion compartment

(corresponding to 1-2 kg). Place 5-8 pieces of kindling randomly on top. Place 2 firelighters between the

top layer of kindling. Light up the fire-lighters and close the stove door. If condensation forms on the

Summary of Contents for 4110

Page 1: ...User s Manual EN AUTOPILOT 15 09 2020 97 9706 www hwam com 4110 4120 4150 4140 4130 4160 4240 ...

Page 2: ......

Page 5: ...Page 5 of 20 pages E1 ...

Page 6: ...Page 6 of 20 pages E2 ...

Page 7: ...Page 7 of 20 pages E3 ...

Page 9: ...Page 9 of 20 pages H ...

Page 20: ...www hwam com ...