14

The stove is EN 13240 approved for firing wood only. No particle board, lacquered, painted or

treated wood, plastics, or rubber may be burned.

m

aIntEnancE

Cleaning

Regularly ensure that the air slit for the pane air rinse function (drawing C, 3) is free of ash and soot

particles . Any maintenance of the stove should only be carried out when it is cold . Daily maintenance is

limited to vacuum cleaning the stove externally, using the soft brush attachment . You can also dust the

stove using a dry, soft cloth or brush . But remember, only when the stove is cold . Do not use water, spirit

or any other kind of cleaner, as this will damage the lacquer .

If the glass door is grimed with soot, it can be cleaned with slightly dampened paper that has been dipped

in the ashes . The outside of the glass can be cleaned with ordinary cleaning solvent used to polish surfaces .

We recommend wiping down the window pane when the insert is not in use/cool .

Once a year, the stove should be thoroughly serviced . The combustion chamber should be cleared of ashes

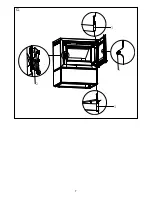

and soot . The hinges and the closing hook must be greased with liquid copper fat spray (heat-resistant

up to 1100 °C), see drawing G .

Service inspection

At least once every other year, the insert should receive a thorough, preventative service inspection .

Among other things, the service inspection covers:

• A thorough cleaning of the insert.

• Check the spring in the automatic unit and replace if necessary.

• Checking gaskets. Replace gaskets if they are not intact or are no longer soft.

• Inspection/possible replacement of heat insulation material.

• Use copper grease for hinges and locking hooks (see drawing G) .

The inspection must be performed by a qualified professional. Use only original spare

parts.

Inside cleaning

Before chimney sweeping can be performed, the adjustment bar must be set all the way to the left to

prevent soot and ash from entering the automatic control .

Drawing C:

Remove the smoke shelf (1) . Push the plate forward and lift it up a bit to the side . Tilt one side downward .

The plate is now free and can be removed from the combustion chamber . Lift the steel smoke deflector

plate (2) off of the hooks so that it can be removed .

Ash

We recommend removing ash from the combustion chamber with an ash suction device .

Ash can be disposed of through daily refuse collection . Be aware that embers in the ash can remain hot

up to 24 hours after the fire in the insert has gone out!

Insulation

The efficient, but porous insulation of the combustion chamber may, in time, be worn and damaged . Cracks

in the insulation are irrelevant to the efficiency of the stove . However, it should be replaced when, due

to wear and tear, it has been reduced to less than half its original thickness .

Summary of Contents for F 30

Page 2: ......

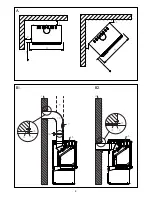

Page 4: ...4 1 2 4 3 1 4 3 1 A 1 1 14 12 13 1 1 14 12 13 9 10 15 15 17 16 B1 B2...

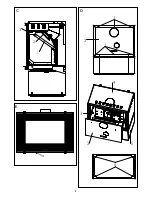

Page 5: ...5 1 1 2 3 C 2 1 1 5 4 3 2 6 D E...

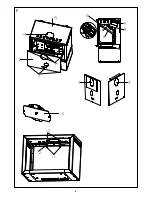

Page 6: ...6 14 15 4 3 6 9 7 8 5 2 1 1 10 12 11 13 F...

Page 7: ...7 2 1 3 3 G...

Page 48: ......