ZX7-315/400/500/630IGBT OPERATOR’S MANUAL

- 10 -

Put the switch 9 to local control position, then all the control can operate through the front panel.

Put the current/voltage select switch to current adjust position, adjust the welding current adjust knob,, the

digital meter will indicate the related preset current value, you can adjust the current value to what you

expect.

Adjust the arc force current knob to related value

Adjust the hot current knob to meet the needs for arc striking.

All the above step finish, the machine can begin to work, what the digital meter indicate during the welding

process is the exact welding current.

2. Remote control

Connect the remote control box with the remote control connector, put the remote/local control switch to

remote control position, then the current is adjusted through the remote control box, adjust method is the

same as above.

3. Arc force current adjust

When use small current to weld, properly adjust the arc force current can increase the short circuit current

value to avoid electrode adhere with work piece, so that the molten drop can easily pass through to

complete welding. Usually for the average current welding, the arc force current can decrease even to zero,

so that it can reduce spatter.

4. Hot current adjust

When use small current welding, properly adjust the hot current can increase the arc striking success ratio.

9. Maintenance

Install and operate the machine strictly according to the operator's manual, the warranty period is one year.

10. Troubleshooting

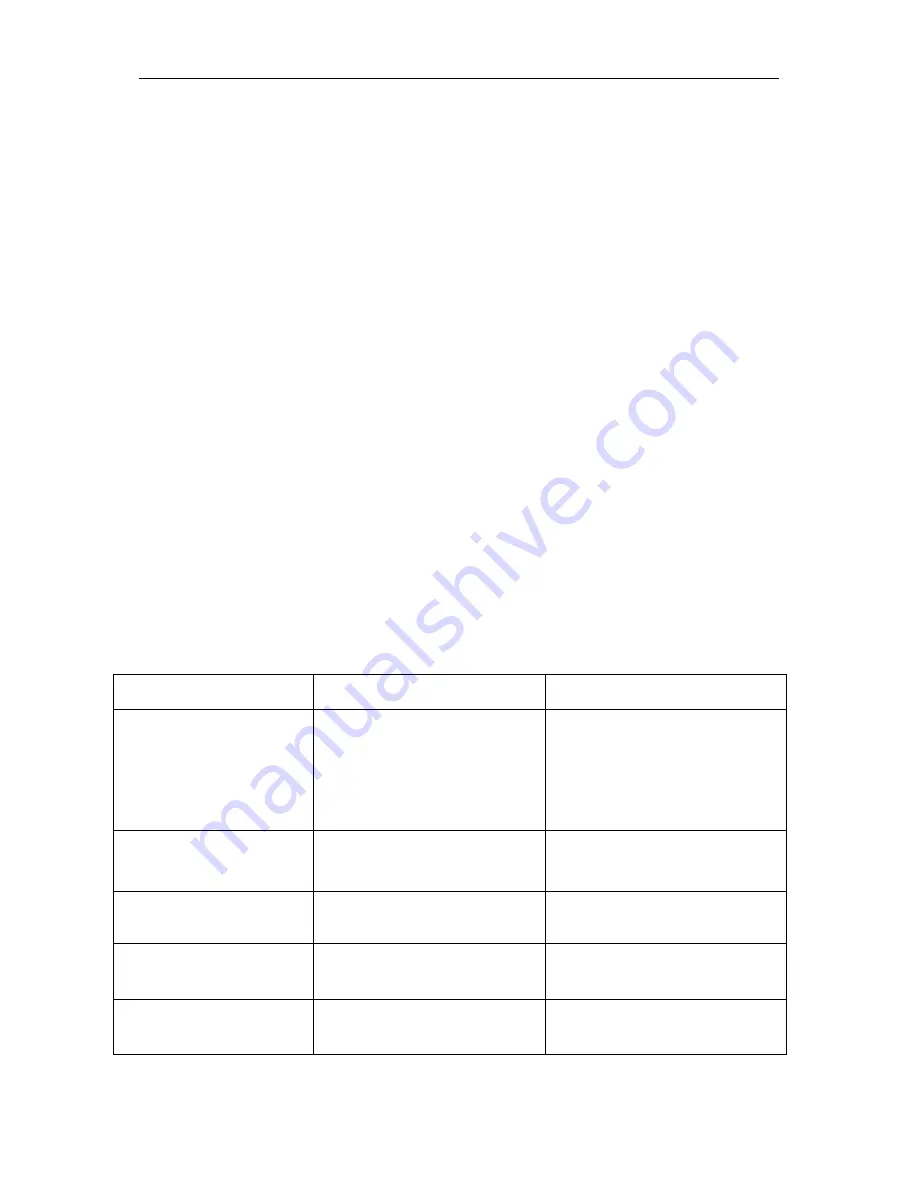

TROUBLE (SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED COURSE OF

ACTION

When machine energized, the

circuit breaker trip

1.Three phase bridge rectifier may

damaged

2. The capacitor which parallel with

the three phase bridge rectifier may

damaged.

3. IGBT may damaged

1.change the bridge rectifier

;

2. change the capacitor.

3. Replace PCB and IGBT

2.

When machine energized, the

power indicator not on, no

voltage indication

1.The protective fuse on the back of

the machine may break

2.Lack phase

1.Replace fuse

2.Check the input power

When machine energized, the

power indicator on, but no

voltage indication

1. PCB AP1 may damage

2.IGBT module may damage

3.Voltmeter may damage

1.Replace AP1

2.Replace IGBT module

3.Replace voltmeter

No OCV, there is abnormal

noise from the machine

FRD on the main circuit is damaged

1.Check and replace the FRD

The

OCV

is

OK,

but

sometimes the arc will break

Lack-phase

Check the input power