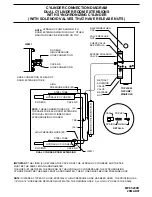

12 VOLT D.C.

HYDRAULIC

POWER UNIT

M

RELIEF VALVE

RETURN

PRESSURE

SOLENOID MANIFOLD

ASSEMBLY

CHECK

VALVE

INNER

CHECK

VALVE

OUTER

SOL.VALVE

LR

SOL.VALVE

SOL.VALVE

SOL.VALVE

RF

RR

LF

PRESSURE/RETURN

SHUTTLE VALVE

50 PSI

SWITCH

JACK

CYLINDER

LEFT REAR

RIGHT REAR

RIGHT

FRONT

LEFT

FRONT

HYDRAULIC SCHEMATIC

305/310/325 SERIES LEVELING SYSTEM

WITH STRAIGHT-ACTING JACKS

07MAR03

MP65.3005