MP45.12

29JAN01

MAINTENANCE

with rebuilt parts or can be sent to HWH CORPORATION to

be rebuilt, when the system is out of warranty.

UNUSUAL CONDITIONS

approximately one inch below the top of the reservoir when

Do not move the vehicle while the leveling jacks are still in

OIL LEVEL

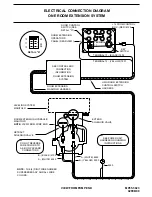

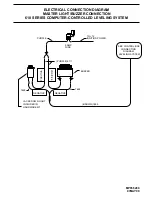

ELECTRICAL SYSTEM

The batteries should be in good condition and fully charged.

Weak batteries can cause erratic operation. Battery cable

terminals and battery posts and connections should be kept

clean.

All electrical connections, especially ground connections,

should be clean, tight, free from corrosion and protected

from weathering.

OPERATIONAL CHECK

If the red LOW BATTERY indicator light comes on, the

electrical system should be checked. If the light comes on,

can cause erratic operation or damage components.

Contact your dealer or HWH CORPORATION for assistance.

Review the JACK RETRACTION Section.

Make sure the jacks will fully retract to the store position.

Jacks should not interfere with any part of the vehicle when

in the store position.

With the jacks extended, check that the jacks can be

retracted using the "T" handles on the solenoid valves.

Refer to the MANUAL JACK RETRACTION Section.

contact with the ground. Retract the jacks according to the

"JACK RETRACTION" Section and then visually check to

see if the leveling jacks have returned to the

STORE/TRAVEL position.

It is important that the four leveling jacks and the room are

fully retracted before checking the hydraulic oil level. To

check the oil supply, remove the breather cap from the top of

the hydraulic oil reservoir. The oil level should be

NOTE: All major components of the system can be replaced

NOTE:

adequately filled.

FLUID: HWH Specialty Hydraulic Oil is recommended. In an

brake fluid or hydraulic jack fluid. Use of these can damage

and can cause staining should a leak occur. DO NOT USE

Dexron automatic transmission fluid contains red dye

emergency Dexron automatic transmission fluid can be used.

seals.

NOTE:

If driving conditions are unusually muddy, the jacks may

become caked or clogged with mud. This condition may

hamper the proper operation of the leveling system. This

problem may be prevented or remedied by cleaning off each

leveling jack if they become excessively muddy.

In wet or icy weather leveling jacks may become encrusted

with ice. This may cause the leveling system to function

improperly. To eliminate this problem, periodically check the

leveling jacks and break loose any ice which may be causing

improper operation.

Review the operator manual and run the system in the

automatic and manual mode. Note any abnormal

operation.

Check that all lights work according to the INDICATOR

LIGHT section. Correct function of the four red WARNING

lights is essential to the correct operation of the system.

Check that the vehicle is level when all the yellow LEVEL

indicator lights are out.

The level sensing unit has an accuracy tolerance of

+ or - 1 inch side to side, and + or - 5.4 inches front to rear

on a 36 foot vehicle.

the operation of the system is not interrupted, but low voltage