C:\TEMP\ml59101.doc | Revised: 20JUN18 | Page 8 of 39

PART 2 – TROUBLE SHOOTING

TROUBLE SHOOTING BASICS (Please read before continuing)

When trouble shooting the 700 series air leveling system, it is best to run the system in the manual mode to check individual

functions before operating the system in the automatic mode. If the system won’t work in manual, it won’t work in automatic.

It is important to remember the HWH works with the vehicle suspension to achieve leveling or ride height. Each HWH

air manifold has 6 valves, a right and left travel valve, a right and a left lower valve and a right and a left raise valve.

There is a manifold for the front axle and the rear axle. A travel valve allows air to pass through the manifold from a

Height Control Valve to the air bag so the Height Control Valves can control the suspension. A lower valve allows air

to exhaust from the air bag to lower the vehicle. A raise valve allows air to flow into the air bag to raise the vehicle.

How high of low a vehicle can go is a function of available air pressure and the limitations of the suspension

equipment, air bags, shocks, etc.

Start the engine and push the “TRAVEL MODE” button. Let air pressure build and allow the vehicle to return to travel height.

This will make the following procedures easier to perform. If the vehicle will not return to travel height, see Step 2.

When trouble shooting, it is important to pay attention to the air bags instead of just watching the vehicle.

Because air

is highly compressible, watching the vehicle move up or down can give you a false impression of what is really happening.

When checking to see if a lower valve is working, wait until air stops exhausting then check that the air bags corresponding to

the DOWN arrow button being pushed are totally empty or flat. When checking to see if a raise or travel valve is working,

make sure there is adequate air supply and check the air bags corresponding to the UP arrow being pushed or if working on

the TRAVEL MODE, all the air bags should have re-inflated. This is the most reliable way to make sure the system is

functioning properly. It is best to check all four sets of UP and DOWN arrows. First use the DOWN arrow and check the

appropriate bags are empty then push the corresponding UP arrow and make sure the bags have re-inflated.

Each air manifold is equipped with two 20 psi pressure switches, one for each side. These are normally closed switches. The

contacts will open at approximately 20 psi. These switches are used as a warning device when traveling and also to establish

the high corner of the vehicle for automatic leveling. If the ignition is on and the park brake is off, one (1) minute after an air

bag pressure switch comes on, the green TRAVEL MODE light will go out and the master warning light will come on. The drive

axle manifold also has an 85 psi switch that monitors vehicle air system pressure. This switch is only used as a warning

device. If the ignition is on and the park brake is released the TRAVEL MODE light will turn off and the master warning light

will turn on as soon as the switch comes on.

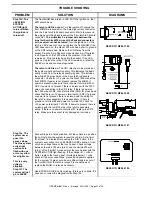

The air manifold MIOMs are equipped with LEDs that can assist with diagnostics. Refer to electrical diagrams for LED

information.

Lit LEDs indicate there is an output but LOW VOLTAGE must always be considered and addressed. When

asked to check for +12 power or voltage and ground, ignition voltages should be above 10.5 volts and output

voltages should be above 10.0 volts. Equipment will work at a lower voltage but levels below 10.0 – 10.5 volts may

indicate a connection, corrosion or battery issue. ALL VOLTAGES SHOULD BE CHECKED UNDER LOAD.

The trouble shooting steps start on the next page. The “Steps” are written in order of operation of the system. If

you are not familiar with the system, skipping steps can cause diagnostic issues. As you proceed through the

different Steps, it is assumed everything in previous Steps has been checked and is working as it should.

The “Steps” direct an operation and explain what should happen. Possible symptoms are listed in the “PROBLEM”

column. Diagnostics and repair solutions are in the “SOLUTION” column. Diagrams are in the “DIAGRAM” column

and also refer you to the corresponding diagram in the diagram section at the rear of this manual. These diagrams

will give you a complete view of the object you are dealing with.