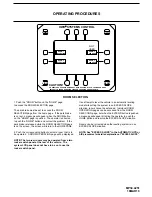

MAINTENANCE

In general, to insure the smooth operation of the leveling

system, it is a good idea to occasionally check the individual

leveling units to prevent problems. This is especially true

under the unusual conditions stated in the following:

If driving conditions are unusually muddy, the units may

become caked or clogged with mud. This condition may

hamper the proper operation of the leveling system. This

problem may be prevented or remedied by cleaning off each

leveling unit if they become excessively muddy.

In wet or icy weather leveling units may become encrusted

with ice. This may cause the leveling system to function

improperly. To eliminate this problem, periodically check the

leveling units and break loose any ice which may be causing

Do not move the trailer while the leveling units are still in

All major components of the system can be replaced

with rebuilt units or can be sent to HWH CORPORATION to

be rebuilt, when the system is out of warranty.

contact with the ground. Visually check to see if the leveling

units have returned to the STORE/TRAVEL position before

moving the trailer.

MP44.0017

13NOV17

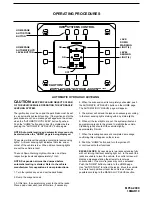

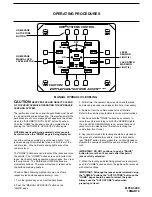

UNUSUAL CONDITIONS

NOTE:

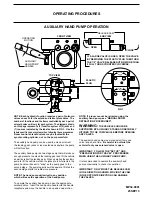

OIL LEVEL

improper operation.

NOT IN PARK/BRAKE CHECK

should now function.

button and set the park brake. The leveling system

LEVEL" button is pushed. Release the "AUTO LEVEL"

BRAKE" indicator light should come on while the "AUTO

Push the "AUTO LEVEL" button. The "NOT IN PARK/

WARNING:

CANNOT ROLL FORWARD OR BACKWARD.

THE COACH WHEELS SECURELY SO THE COACH

to the "ACC" or "ON" position. Release the parking brake.

Apply the brake so the coach cannot roll. Turn the ignition

WHEN MAKING THIS CHECK, BLOCK

qualified RV repair center, your vehicle or coach

or if there are other problems or questions, consult a

If any of the above checks or inspections reveal a problem

manufacturer, or HWH CORPORATION

for service or repair.

WINTER WEATHER DRIVING

components, such as HWH jacks.

have dried. This can facilitate corrosion of metallic

Anti-icing / deicing agents when splashed on your vehicle,

continue to absorb moisture from the air even after they

icing / deicing agents, thoroughly wash jacks with warm

To help reduce the corrosion of jacks after exposure to anti-

soapy water.

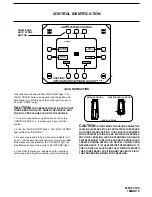

cap before removing.

and steps should be fully retracted before checking fluid

breather cap. Clear any dirt away from the breather / filler

assembly. The oil level is checked and filled through the

level. The oil reservoir is part of the pump / manifold

Any HWH hydraulic equipment, including jacks, slide-outs

servicing of the coach.

All maintenance should be done as part of the normal

there is an oil leak in the system.

purchased and then once every two years. More often if

The oil level should be checked when the vehicle is first

should be between the bottom of the dipstick and the

reservoir. Most breather caps have a dipstick. Fluid level

The oil level should be within one inch of the top of the

emergency Dexron automatic transmission fluid can be used.

Dexron automatic transmission fluid contains red dye

and can cause staining should a leak occur. DO NOT USE

brake fluid or hydraulic jack fluid. Use of these can damage

HWH Specialty Hydraulic Oil is recommended. In an

NOTE: Overfilling the tank can cause leakage of oil

through the breather cap.

center mark.

FLUID:

NOTE:

seals.