Operation & Safety Manual

HB-P4.5 / HB-P5.0

SUPO 647

REV D

16

4.1 | Preliminary Unpacking Instructions and Dealer Inspection

Maintenance locks must be engaged prior to inspecting or servicing the unit when the platform

is elevated. Inspect machine for any possible damage during shipment; perform a pre-delivery

inspection. See checklist in the Maintenance Manual. Reset emergency stop switches, if neces-

sary.

4.2 | Storage

After periods of storage, exposure to extremes of ambient conditions-heat, cold, moisture, dust

etc., inspect the machine. Refer to the Pre-Delivery/ Frequent Inspection Checklist in the Mainte-

nance Manual.

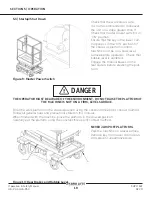

4.3 | Transportation

Lower the work platform to the down position. Turn key

switch to off position. For safety and controlled handling,

it is not recommended to move the unit on a slope greater

than 5°. Check entire machine for loose or unsecured items.

Remove any loose items from machine. Apply manual brake

lock on rear wheels.

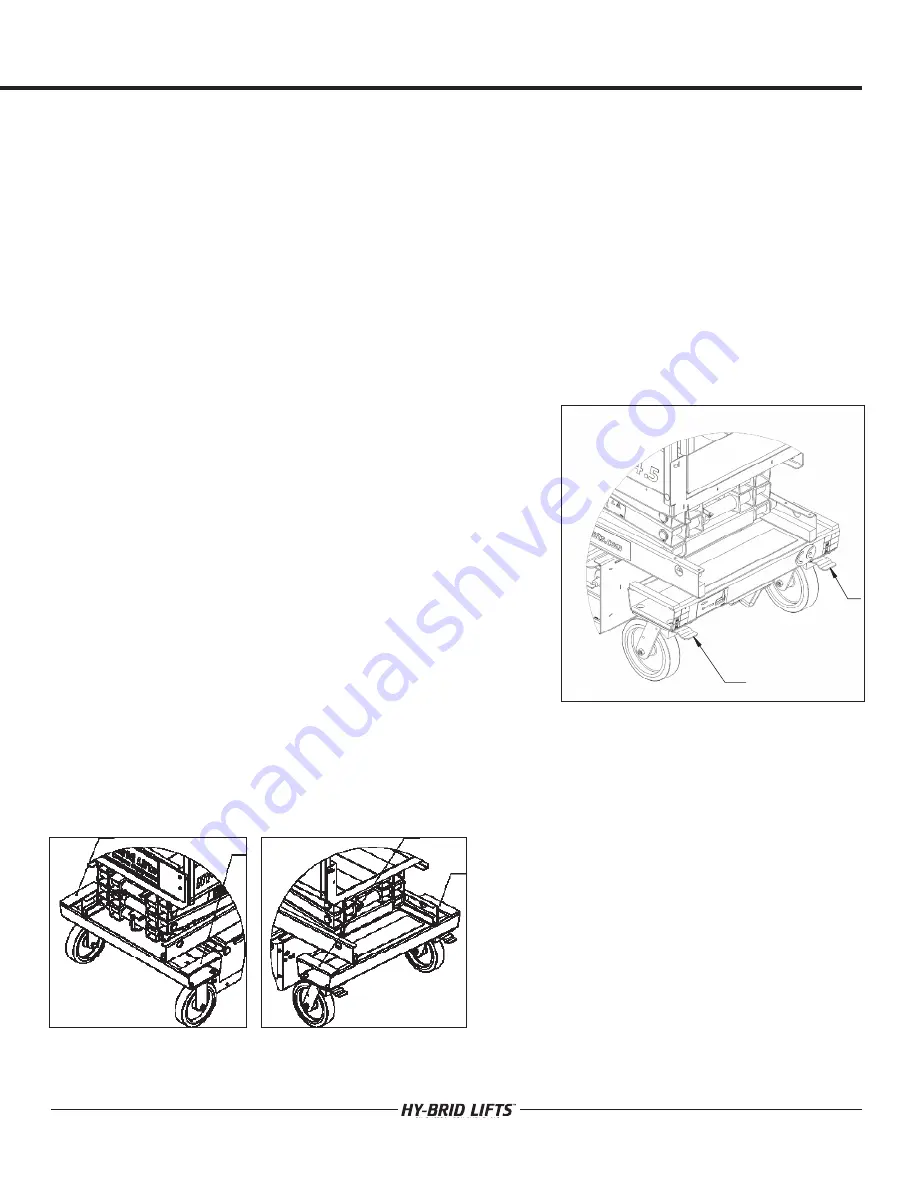

4.4 | Lifting and Tie-Down Points

Lower the work platform to the down position. Turn key

switch to off position. For safety and controlled handling,

it is not recommended to move the unit on a slope greater

than 5°. Check entire machine for loose or unsecured items. Remove any

loose items from machine. Apply manual brake lock on rear wheels.

B

Figure 6: Rear Brakes

Figure 5: Tie-Down Points

Tie-down points are provided in the front

and rear of the machine for securing the

machine on a trailer or truck bed for trans-

port between places of use. They may also

be used as lift points.

SECTION 4 |

TRANSPORT, HANDLING & STORAGE