SECTION 2 | SAFETY

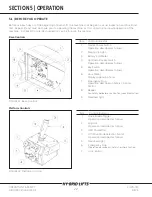

2.6 | MAINTENANCE LOCK

The maintenance chock must be placed into position whenever the machine is being serviced in the raised or

partially raised position. Serious injury and/or death could result if maintenance lock is not used properly.

2.7 | SAFETY GUIDELINES

Only qualified operators may operate this unit.

•

All operators must read and understand the Operation and Safety Manual. They must understand all decals and

warning labels on unit.

•

Do not work on platform if your physical condition is such that you feel dizzy or unsteady in any way.

•

Do not neglect/misuse machine. Report any misuse of equipment to proper personnel.

•

Prevent unauthorized use; when unit is not in use, remove key.

•

It is recommended all personnel on unit wear approved personal protective equipment (PPE), i.e. head gear.

Use machine only for purposes for which it was intended.

•

Lift should never be used as a crane.

•

Do not exceed the load capabilities of the platform.

•

Distribute load evenly over platform floor area.

•

Never use unit as electrical grounds for arc welding.

•

Do not override any hydraulic, mechanical, or electrical safety devices.

Check job site for unsafe working conditions.

•

Watch out for others. Keep others clear of operating platform. Never allow others to pass under a raised

platform or position the platform over someone.

•

Avoid contact with fixed objects (walls, buildings, or other machinery, etc) or moving vehicles (automobiles,

cranes, etc).

•

Follow any applicable national traffic regulations.

•

Use indoors only. Lift is not designed for windy conditions or electrical storms.

•

Unit must be on hard level surface before elevating. Do not operate on incline or uneven surface.

FIGURE 4: Maintenance Lock Storage

FIGURE 5: Maintenance Lock Use

BY CUSTOM EQUIPMENT LLC

OPERATIONS & SAFETY

HB-1030CE/HB-1430CE

SUPO-713

REV A

12