Installation and Maintenance Manual

9

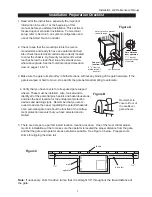

Remember to

cover all four of

the cantilever

gate wheels

fence

1

3

/

4

"

slab

operator

drive rail

1

3

/

4

"

Gate distance

from operator:

1

3

/

4

" back of

drive rail to edge

of operator

Drive rail

location:

9

3

/

4

" from top

of slab to top of

drive rail

concrete slab

safety mesh to prevent

reach-through

Figure C

Figure B

Figure A

Installation Preparation Checklist

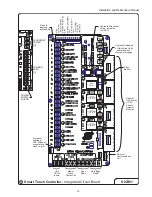

1. Read all of the instructions, especially the Important

Information in Section 1 at the beginning of this

manual, before you attempt installation. This section is

focused upon mechanical installation. For electrical

setup, refer to Section 3, on system configuration and

use of the Smart Touch Controller.

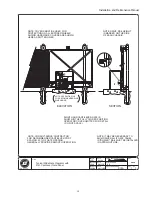

2. Check to see that the mounting slab is the recom-

mended size and ready to have an operator attached.

Also check that electrical conduits are correctly located

to enter the chassis. Hy-Security recommends a slab

reaches below the local frost line and extends some-

what above grade. See the footprint plan and elevation

view on pages 14 & 15.

3. Make sure the gate rolls smoothly in both directions, without any binding of the gate hardware. If the

gate is warped or hard to move, stop and fix the gate before attempting to automate.

4. Verify that you have covers for all exposed gate support

wheels. These must be installed. Also, look around to

identify all of the potential pinch points and hazardous areas,

and plan the best location for the entrapment protection

devices and warning signs. Remember that you are re-

quired to advise the owner regarding the potential hazards

of an automatic gate and about the function of the entrap-

ment protection sensors that you have selected and in-

stalled.

5. There are 3 steps to a perfect install: location, location, location. One of the most critical adjust-

ments in installation will be to make sure the operator is located the proper distance from the gate,

and that the gate and operator are as parallel as possible. See Figure C below. Prepare some

shims for aligning the drive rail.

Note: If necessary, shim the drive rail so that it is straight 1/4" throughout the travel distance of

the gate.