Installation and Maintenance Manual

13

OFF

POWER

ON

Optional brake valves CCW = quicker stop.

Left valve controls open

Right valve controls close

Mechanical and Hydraulic Adjustments

1. Drive Wheel Spring Tension

When the drive wheels are fully clamped on the rail, the red spring should be compressed to 2" in

height. If adjustment is necessary, turn the nut at the bottom of the threaded rod assembly. Slightly

less compression is okay for lighter gates. (See Figure on page 11, and full details on page 54).

2. Drive Rail

Verify that the drive rail does not vary more than 1" up and down, or 1/4" in and out throughout the

entire horizontal travel of the gate. Re-alignment is simple if the rail is mounted with U bolts. To

adjust in and out, loosen the U bolts and add or remove shim stock. To adjust up or down, loosen

the U bolts and simply tap the rail with a hammer until the correct height is reached. Adjusting the

rail in or out requires inserting shims between the rail and the gate where necessary.

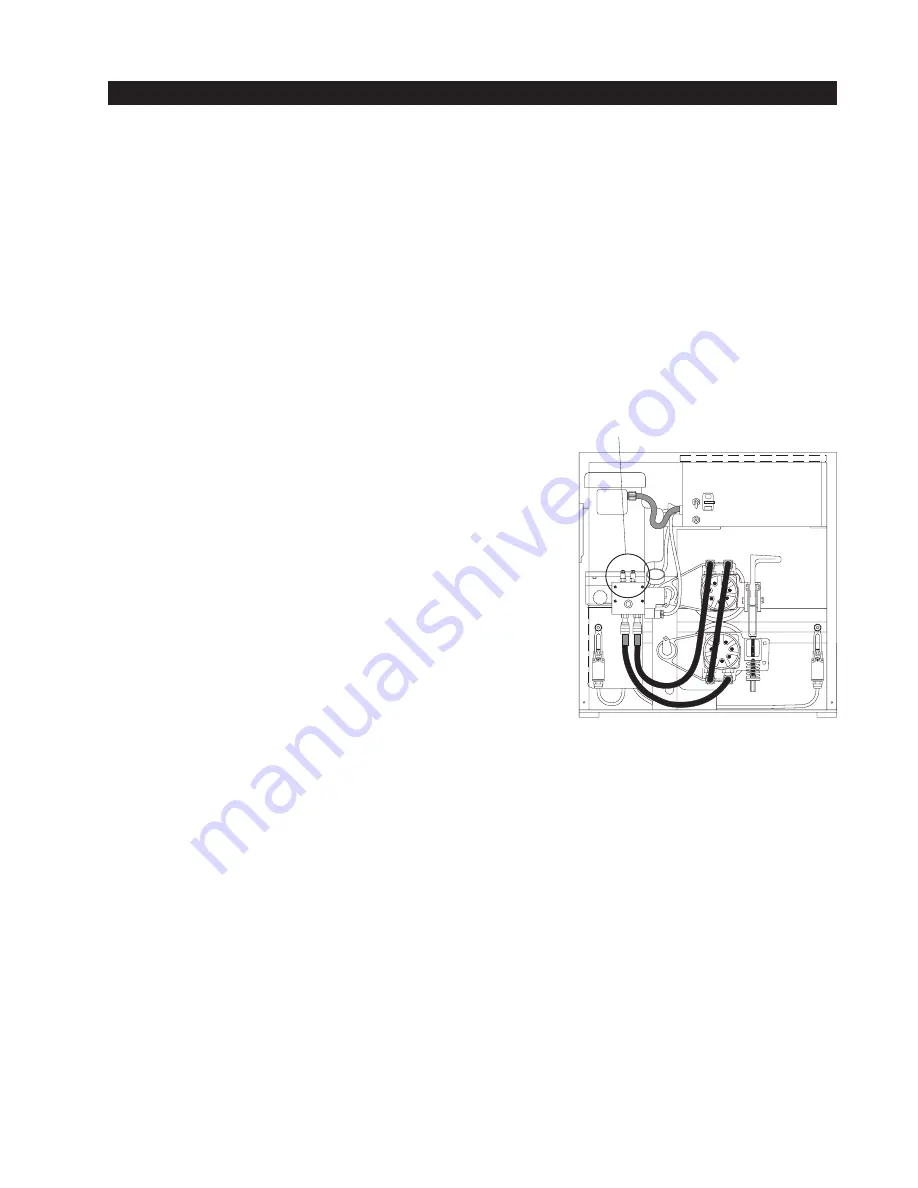

3. Brake Valves (suffix E, EX models only)

If your operator is equipped with brake valves, their proper

adjustment is important for smooth operation of the gate. In

order for the brake valves to have time to function, the limit

ramp must trigger the limit switch at least six inches before

the point at when you want the gate to stop. Adjustment of

the brake valves, one for each direction of travel, will deter-

mine how quickly the gate actually stops. If adjustment is

needed, loosen the 9/16" lock nut on the top of the brake

valve and turn the adjustment stem, in about 1/4 turn incre-

ments, with an Allen wrench. The adjustment works opposite

of typical, such that a counter-clockwise adjustment will stop

the gate more rapidly. If the adjustment is set too loose, the

limit ramps will bang into the drive wheels. If the adjustment

is set too tight, the system pressure will increase, the gate

speed may decrease and the gate will jerk to a stop. Set the

brake valve to achieve a controlled smooth stop, and then

retighten the locking nut to hold the setting.

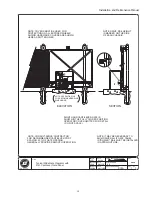

4. Pressure Relief Valve

This valve, which governs the maximum system hydraulic pressure available, is located on the

backside of the pump, just above the limit switch. Installers are encouraged to reduce the relief

valve setting to the lowest pressure that will reliably operate the gate. A lower setting reduces the

maximum force that the gate operator can exert. If adjustment is needed, loosen the 9/16" lock nut

and turn the adjustment stem with a wrench. Lower pressure (force) is achieved by turning the

adjuster stem counter-clockwise. The only way to display the actual relief valve setting is to unplug

the hydraulic hoses from the quick disconnect fittings. Be certain to retighten the locking nut to

hold the desired setting and reconnect the hoses correctly. Also see the drawing in Section 7, page

52 for the location and a schedule of factory pressure relief settings.

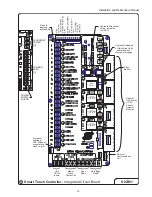

5. Directional and Quick Stop Valves

These two valves are solenoid operated. The directional valve is below the motor near the front of

the pump and energizes in order to direct the hydraulic flow to open the gate. The quick stop valve,

which is near the back of the pump energizes at the beginning of a cycle to allow no load motor

starts and at the end of each cycle to aid in decelerating the gate. No adjustment of these valves is

possible or ever needed.