5

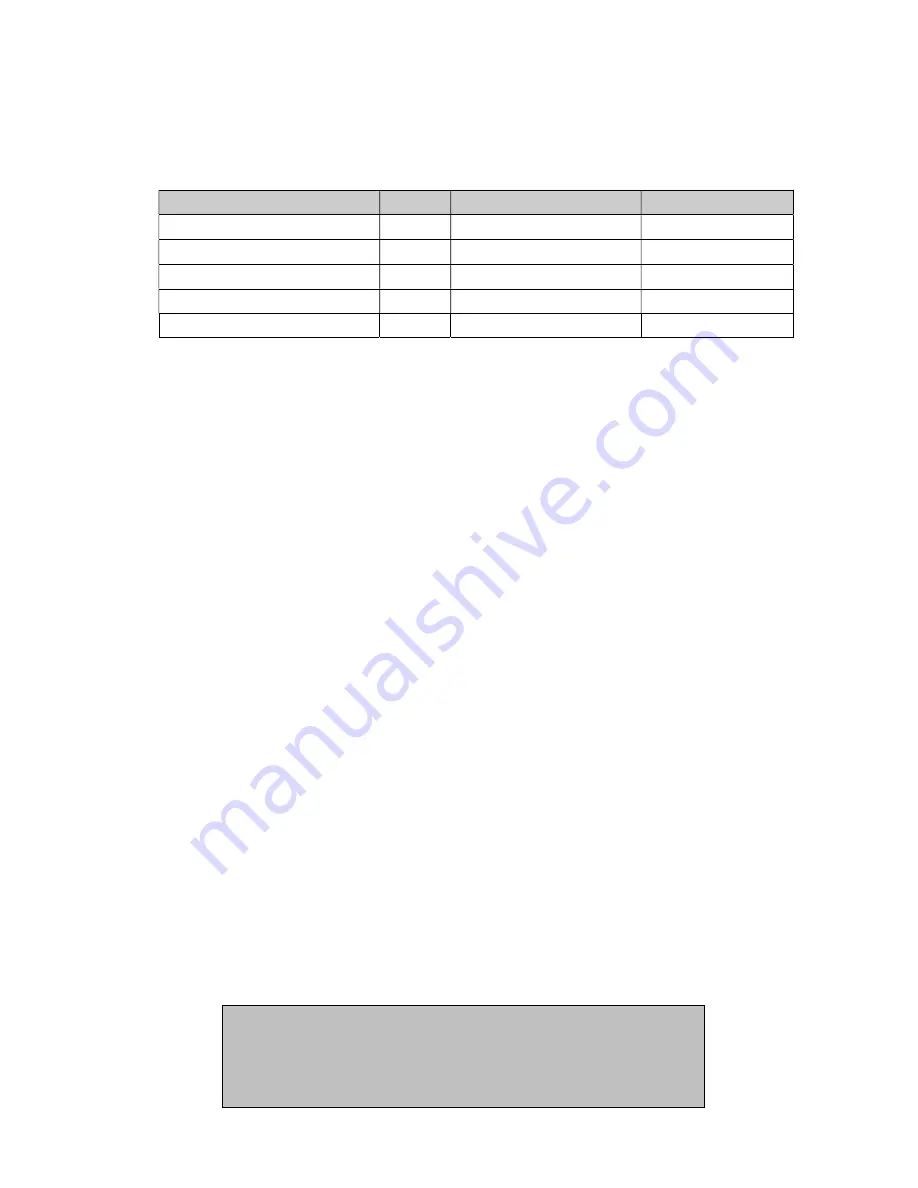

Service, Maintenance and Hydraulic Settings

Service/Maintenance

Daily

Weekly

Yearly

Hydraulic oil

Check

1 x replacement

Hydraulic oil filter *)

1 x replacement

Check hoses

(tighten up if needed)

Air filter

1 x replacement

Fuel filter

1 x replacement

*) use only filters with by-pass

Engine service

The engine must be serviced according to the Lombardini service book

Hydraulic Settings

Check the working pressure by means of test equipment.

The test equipment must

comprise a pressure gauge, a flow meter and a valve for adjustment of pressure.

The pressure relief valves are placed on the valve block. There are two pressure

relief valves (one for each hydraulic circuit), and they must be adjusted individually.

The pressure relief valves are marked with B and C respectively.

1. Connect the test equipment to connection B, start the powerpack and move the B

lever to ON and the A and C levers to OFF. Then close the valve on the test

equipment and adjust the pressure relief valve B according to the technical data.

Adjust the pressure relief valve by loosening the lock nut and turning the

adjustment screw in or out. “In” increases the pressure, and “out” decreases the

pressure.

Retighten the lock nut after adjustment.

Connect the test equipment to connection C, start the powerpack and move lever

C to ON and levers A and B to OFF. Then close the valve on the test equipment

and adjust the pressure relief valve C according to the technical data.

2. Having adjusted the pressure relief valves correctly, set the working pressure to

100 bar by means of the valve on the test equipment. At 100 bar the oil flow

should correspond to the flow rate which the lever is set at (see Setting of Flow).

If correct pressure/oil flow cannot be achieved by following

the above instructions, the powerpack must be re-adjusted.

If the pressure/oil flow is then still incorrect, the pump is

defect and must be replaced.