10

−

4

124

Use and maintenance manual DM-1215

SOLUTION

PROBABLE CAUSE

PROBLEM

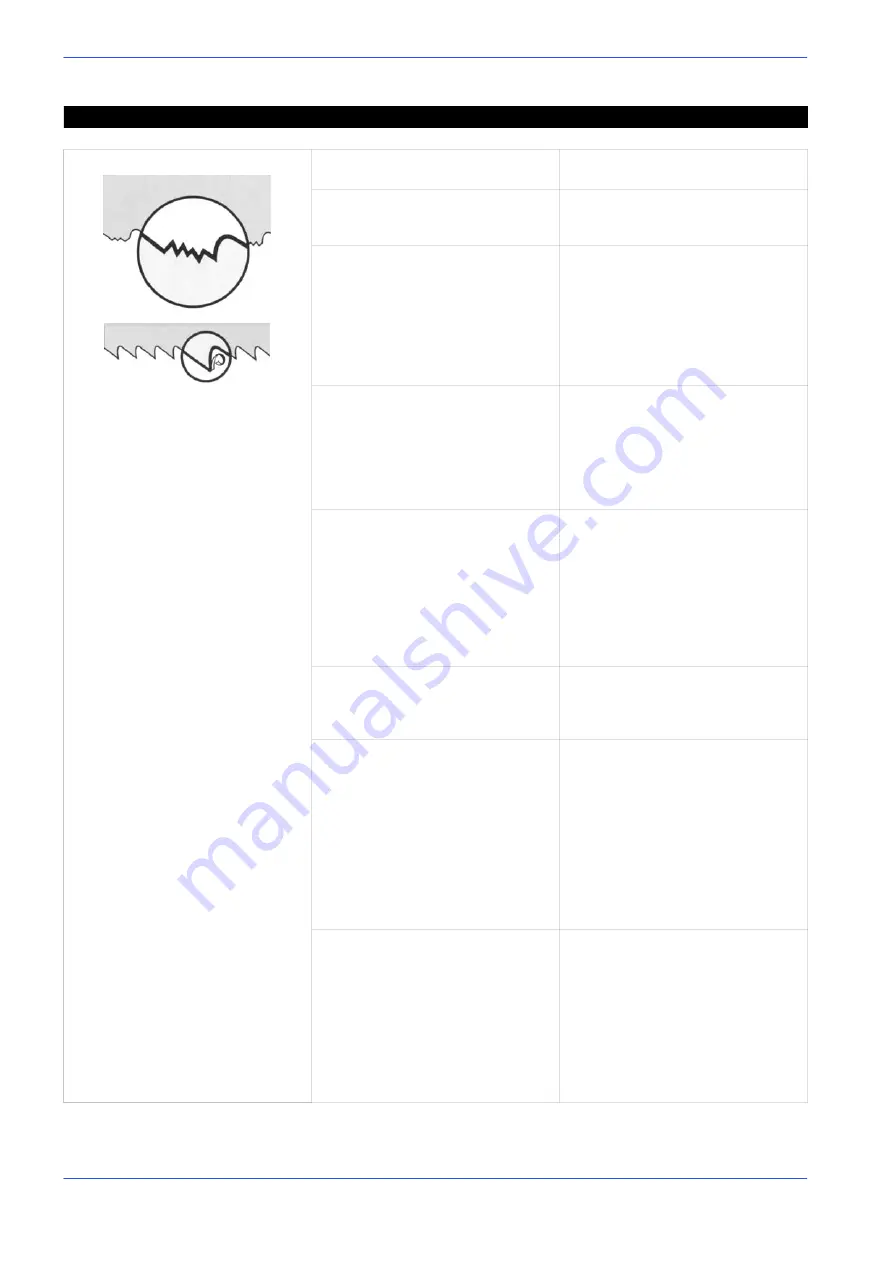

Broken teeth

Cutting pressure too high

Check and set to correct

pressure

Tooth pitch unsuitable

Teeth too close together:

change blade for one with a

coarser tooth pitch

Swarf welded to teeth and

gullets

Check blade

−

cleaning

coolant jets. Check the

blade

−

cleaning brush. If the

swarf is not removed from

the blade it will be drawn

back into the cut and weld to

the teeth, causing tooth

breakage

Swarf welded to teeth and

gullets

Check blade

−

cleaning fluid

jets. Check blade

−

cleaning

brush. If the swarf is not re-

moved from the blade it will

be drawn back into the cut

and weld to the teeth, caus-

ing the teeth to break.

Material defects

The material may have al-

tered surface areas, such as

oxides or sand, or subcooled

inclusions in the section.

These areas are much hard-

er than the blade and will

cause the teeth to break:

scrap or clean these materi-

als.

Workpiece not clamped

The blade may break if the

workpiece moves during cut-

ting: check the vice, jaws and

clamping pressure

The blade stops in the cut

Cutting pressure too high:

check and restore to rated

pressure. Downstroke speed

too fast: reduce speed. Cut-

ting speed too slow: in-

crease. The blade slips on

the flywheels: either the

wheels are worn and need to

be replaced or the blade ten-

sion is incorrect (too low) and

must be re

−

adjusted.

New blade inserted in a par-

tially made cut

The cutting surface may

have been subjected to a lo-

calised heat

−

induced alter-

ation, making it harder:

recommence cut using a

slower cutting and down-

stroke speed. A tooth from

the old blade may be left in

the cut: check and remove

before restarting work.

Summary of Contents for DM-1215

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ DM 1215 EN ...

Page 2: ......

Page 4: ......

Page 34: ......

Page 53: ...6 7 52 Diagrams exploded views and replace Standardised Wiring Diagrams ...

Page 54: ...6 8 53 Use and maintenance manual DM 1215 ...

Page 55: ...6 9 54 Diagrams exploded views and replace ...

Page 56: ...6 10 55 Use and maintenance manual DM 1215 F6 F7 F8 F3 F4 F5 RT4 ...

Page 57: ...6 11 56 Diagrams exploded views and replace F1 F2 F9 ...

Page 58: ...6 12 57 Use and maintenance manual DM 1215 S4 KSTO S8 S4 K01 ...

Page 59: ...6 13 58 Diagrams exploded views and replace KSTO KSTO RT4 ...

Page 61: ...6 15 60 Diagrams exploded views and replace ...

Page 62: ...6 16 61 Use and maintenance manual DM 1215 ...

Page 63: ...6 17 62 Diagrams exploded views and replace ...

Page 64: ...6 18 63 Use and maintenance manual DM 1215 ...

Page 65: ...6 19 64 Diagrams exploded views and replace ...

Page 66: ...6 20 65 Use and maintenance manual DM 1215 ...

Page 67: ...6 21 66 Diagrams exploded views and replace ...

Page 68: ...6 22 67 Use and maintenance manual DM 1215 ...

Page 69: ...6 23 68 Diagrams exploded views and replace ...

Page 70: ...6 24 69 Use and maintenance manual DM 1215 ...

Page 71: ...6 25 70 Front flywheel assembly ...

Page 74: ...6 28 73 Use and maintenance manual DM 1215 Motor flywheel assembly ...

Page 77: ...6 31 76 Cutting head cover ...

Page 79: ...6 33 78 Vice assembly ...

Page 81: ...6 35 80 Base assembly ...

Page 83: ...6 37 82 Control panel ...

Page 85: ...6 39 84 Fixed work table and turntable ...

Page 88: ...6 42 87 Use and maintenance manual DM 1215 Cylinder unit ...

Page 90: ...6 44 89 Use and maintenance manual DM 1215 Laser and lamp group ...

Page 92: ......

Page 132: ......

Page 136: ......