3.3

BLADE GUIDE ADJUSTMENT

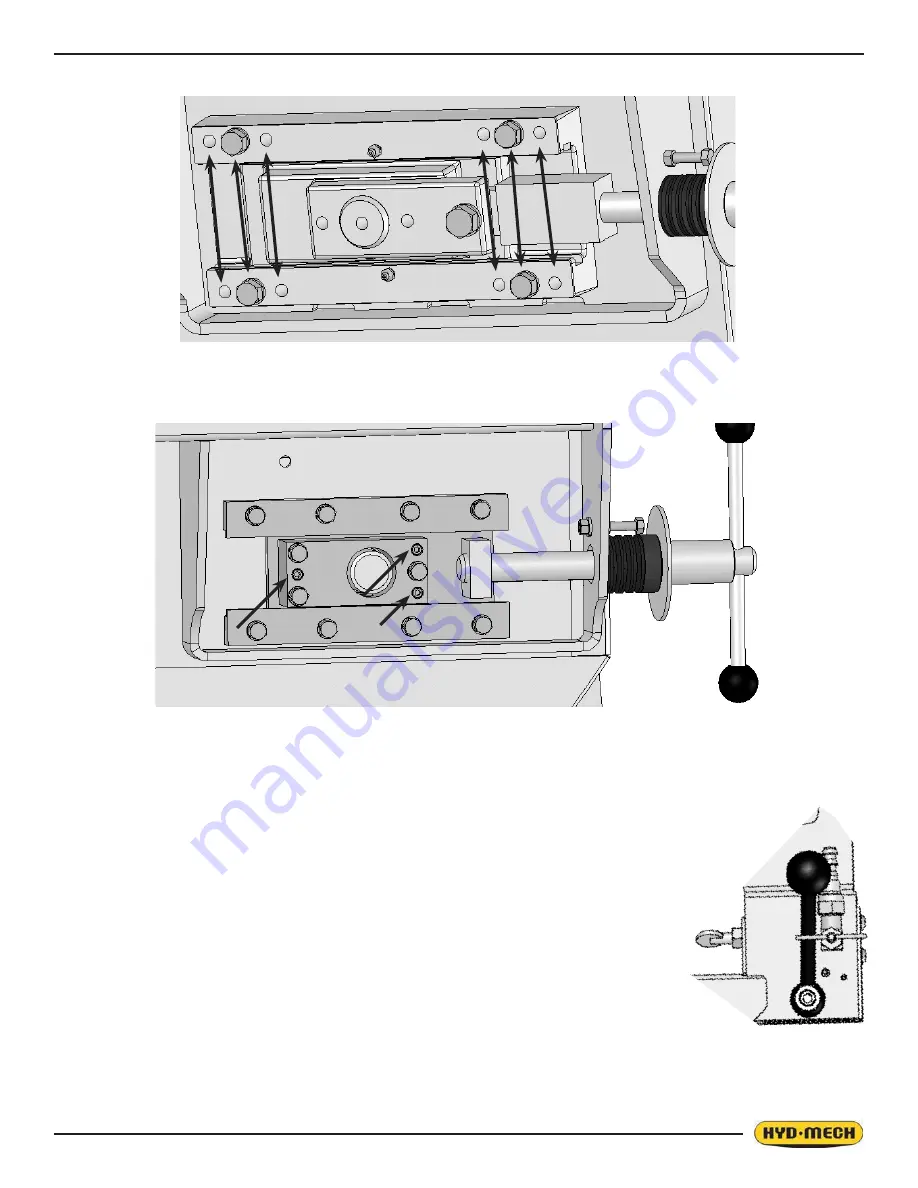

At the bottom of the guide arms are the carbide blade guide assemblies, the photo shows the carbide-locking

handle. These assemblies will need to be adjusted occasionally as the carbide pads become worn. To adjust

properly, follow this simple procedure. Loosen the hex nut on the locking handle with a 9/16 wrench and

turn the handle clockwise until it rests against the coolant tap on the idler guide arm or the roll pin on the

drive guide arm. Turn the setscrew clockwise with a 3/16 Allen key until tight and then loosen 1/8 turn

and tighten the hex nut. This should put just enough pressure on the blade to permit you to push

the blade down approximately 1/8” (3.2mm).

C

C

A

B

D

D

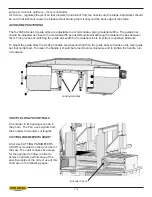

S-23 BLADE TENSION ASSEMBLY

S-20 BLADE TENSION ASSEMBLY

Summary of Contents for S-20 A

Page 2: ......

Page 16: ...1 4 ...

Page 54: ......

Page 55: ...4 1 SECTION 4 ELECTRICAL MAIN PANEL COMPONENT LAYOUT ...

Page 58: ...4 4 MAIN PANEL COMPONENT LAYOUT 1OL 2OL VFD 1M 2M POWER SUPPLY ...

Page 63: ...5 3 FOR HYDRAULIC SCHEMATICS AND PLUMBING DIAGRAMS SEE PDF ON ATTACHED CD ...

Page 64: ......

Page 65: ...6 1 SECTION 6 MECHANICAL ASSEMBLIES For Mechanical Assembly Drawings see PDF on attached CD ...

Page 66: ......

Page 70: ......

Page 72: ...8 2 ...

Page 73: ...8 3 ...

Page 74: ...8 4 ...

Page 76: ...8 6 ...

Page 77: ...8 7 ...

Page 78: ...8 8 ...