Pg 3.13

S23H

BLADE TRACKING ADJUSTMENT, CONTINUED

10B.

Drive Wheel Adjustment. -- On the wall behind the drive wheel are two adjusting

bolt assemblies and two hex bolts. Loosen all four of them with a 3/4" socket and turn

the larger hex head bolts 1/4 turn with a 1 1/8" socket and extension and then tighten

the two bolts in the assemblies, then tighten the two hex bolts at the left. Turning the 1

1/8" bolts clockwise will pull the blade in and turning counter clockwise will push the

blade out. Each 1/4 turn will move the blade approximtely .02".

11.

Check the blade brush adjustment (as shown below) to be sure the blade is being

cleaned properly.

BLADE GUIDE ADJUSTMENT

At the bottom of the guide arms are the carbide blade guide assemblies, the

photo below shows the carbide locking handle. These assemblies will need to

be adjusted occasionally as the carbide pads become worn. To adjust properly,

follow this simple procedure. Loosen the hex nut on the locking handle with a 9/

16 wrench and turn the handle clockwise until it rests against the coolant tap on

the idler guide arm or the roll pin on the drive guide arm. Turn the set screw

clock wise with a 3/16 allen key until tight and then loosen 1/8 of a turn and

tighten the hex nut. This should put just enough pressure on the blade to permit

you to push the blade down approximately 1/8".

Idler guide arm carbide

locking handle in the

locked position.

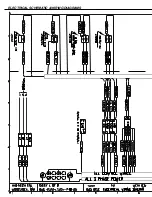

Drive wheel

tracking bolt

assemblies

BLADE BRUSH ADJUSTMENT

The S-23 leaves the factory with the blade brush adjusted for maximum life of

the brush. This setting places the ends of the blade brush wires so as to contact

the blade at the bottom of the blade gullets. The plastic drive wheel that is driven

by the drive wheel face should be held against the blade face with the minimum

force that is necessary. As the blade brush wears it is necessary to periodically

readjust it.

As shown, there are two springs on socket head screws holding the brush

assembly against the blade. There is also an adjusting socket set screw with a

hex nut on it. Loosen the hex nut with a 9/16" wrench and turn the set screw

counter clockwise with a 3/16" allen key. This will move the brush closer to the

blade. Adjust the set screw so that the brush cleans to the bottom of the blade

gullets and tighten the hex nut.

Blade brush

adjusting screw.

Summary of Contents for S-23H

Page 1: ...I N B A N D S A W T E C H N O L O G Y OPERATIONS MAINTENANCE M A N UA L ...

Page 3: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 6: ...SECTION 1 INSTALLATION SECTION 1 INSTALLATION ...

Page 7: ...SECTION 1 INSTALLATION ...

Page 12: ...SECTION 2 OPERATING INSTRUCTIONS SECTION 2 OPERATING INSTRUCTIONS ...

Page 13: ...SECTION 2 OPERATING INSTRUCTIONS ...

Page 19: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 20: ...SECTION 3 MAINTENANCE AND TROUBLE SHOOTING SECTION 3 MAINTENANCE AND TROUBLE SHOOTING ...

Page 21: ...SECTION 3 MAINTENANCE AND TROUBLE SHOOTING ...

Page 28: ...Pg 3 17 S23H SERVICE RECORD NOTES DATE SERVICED BY COMMENTS ...

Page 29: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...SECTION 4 ELECTRICAL SYSTEM SECTION 4 ELECTRICAL SYSTEM ...

Page 31: ...SECTION 4 ELECTRICAL SYSTEM ...

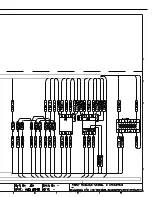

Page 35: ...ELECTRICAL SCHEMATIC WIRING DIAGRAMS ...

Page 36: ......

Page 37: ...ELECTRICAL SCHEMATIC WIRING DIAGRAMS ...

Page 38: ......

Page 39: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 40: ...SECTION 5 HYDRAULIC SYSTEM SECTION 5 HYDRAULIC SYSTEM ...

Page 41: ...SECTION 5 HYDRAULIC SYSTEM ...

Page 43: ...Pg 5 28 S22 23H CYLINDER ASSEMBLIES Piston assemblies Gland assemblies ...

Page 44: ...Pg 5 29 S22 23H HYDRAULIC SCHEMATIC and PLUMBING DIAGRAM ...

Page 45: ...Pg 5 30 S22 23H ...

Page 46: ...SECTION 6 MECHANICAL ASSEMBLIES SECTION 6 MECHANICAL ASSEMBLIES ...

Page 47: ...SECTION 6 MECHANICAL ASSEMBLIES ...

Page 48: ...Pg 6 31 S23H 2001a GUIDE ARM CARBIDE ASSEMBLIES SECTION 6 MECHANICAL ASSEMBLIES ...

Page 49: ...Pg 6 32 S23H 2001a BLADE DRIVE ASSEMBLY ...

Page 51: ...Pg 6 34 S23H 2001a HM4A GEAR BOX ASSEMBLY ...

Page 52: ...Pg 6 35 S23H 2001a IDLERWHEEL ASSEMBLY 01 2345 1 345 1 6 7809 849 59 9 3 01 1 ...

Page 53: ...Pg 6 36 S23H 2001a BLADE BRUSH ASSEMBLY ...

Page 54: ...Pg 6 37 S23H 2001a COUNTER BALANCE SPRINGASSEMBLY ...

Page 55: ...Pg 6 38 S23H 2001a PIVOT LINK ASSEMBLY ...

Page 56: ...Pg 6 39 S23H 2001a 0 1 Pivot link parts list ...

Page 57: ...Pg 6 40 S23H 2001a FRONTVISE ASSEMBLY ...

Page 58: ...Pg 6 41 S23H 2001a HYDRAULIC POWER PACK ...

Page 61: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 62: ...SECTION 7 OPTIONAL ASSEMBLIES SECTION 7 OPTIONAL ASSEMBLIES ...

Page 63: ...SECTION 7 OPTIONAL ASSEMBLIES ...

Page 64: ...Pg 7 45 S23H SECTION 7 OPTIONAL ASSEMBLIES WORK STOP ...

Page 67: ...Pg 7 48 S23H 30O MITRE CUTTING ...

Page 68: ...SECTION 8 SPECIFICATIONS SECTION 8 SPECIFICATIONS ...

Page 69: ...SECTION 8 SPECIFICATIONS ...

Page 71: ...Pg 8 50 S23H LAYOUT DRAWINGS ...

Page 72: ...Pg 8 51 S23H ...

Page 73: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 74: ...SECTION 9 WARRANTY SECTION 9 WARRANTY ...

Page 75: ...SECTION 9 WARRANTY ...