Summary of Contents for V-18 APC

Page 2: ......

Page 6: ......

Page 12: ......

Page 28: ......

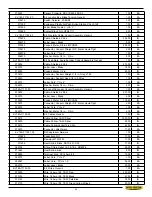

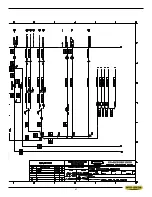

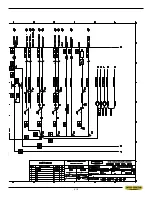

Page 48: ...4 6 V18 APC 208 240 VOLT ELECTRICAL SCHEMATIC NO OPTIONS ...

Page 49: ...4 7 ...

Page 50: ...4 8 ...

Page 51: ...4 9 ...

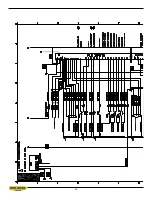

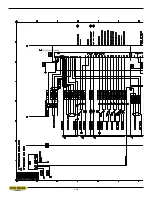

Page 52: ...4 10 V18 APC 208 240 VOLT WIRING DIAGRAM NO OPTIONS ...

Page 53: ...4 11 ...

Page 54: ...4 12 ...

Page 55: ...4 13 ...

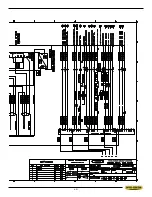

Page 56: ...4 14 V18 APC 208 240 VOLT INPUT AND OUTPUTS NO OPTIONS ...

Page 57: ...4 15 ...

Page 58: ...4 16 ...

Page 59: ...4 17 ...

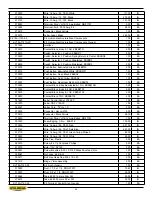

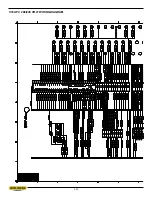

Page 60: ...4 18 V18 APC 208 240 VOLT ELECTRICAL SCHEMATIC ...

Page 61: ...4 19 ...

Page 62: ...4 20 ...

Page 63: ...4 21 ...

Page 64: ...4 22 V18 APC 208 240 VOLT WIRING DIAGRAM ...

Page 65: ...4 23 ...

Page 66: ...4 24 ...

Page 67: ...4 25 ...

Page 68: ...4 26 V18 APC 208 240 VOLT INPUT AND OUTPUTS ...

Page 69: ...4 27 ...

Page 70: ...4 28 ...

Page 71: ...4 29 ...

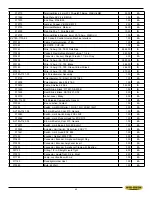

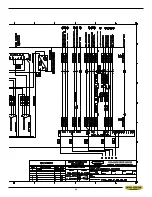

Page 72: ...4 30 V18 APC 480 575 VOLT ELECTRICAL SCHEMATIC NO OPTIONS ...

Page 73: ...4 31 ...

Page 74: ...4 32 ...

Page 75: ...4 33 ...

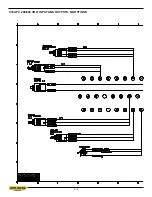

Page 76: ...4 34 V18 APC 480 575 VOLT ELECTRICAL WIRING DIAGRAM NO OPTIONS ...

Page 77: ...4 35 ...

Page 78: ...4 36 ...

Page 79: ...4 37 ...

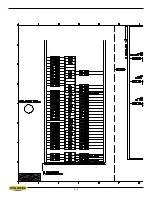

Page 80: ...4 38 V18 APC 480 575 VOLT INPUT AND OUTPUT DEVICES NO OPTIONS ...

Page 81: ...4 39 ...

Page 82: ...4 40 ...

Page 83: ...4 41 ...

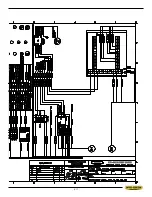

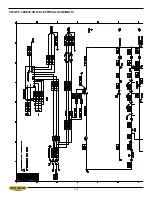

Page 84: ...4 42 V18 APC 480 575 VOLT ELECTRICAL SCHEMATIC ...

Page 85: ...4 43 ...

Page 86: ...4 44 ...

Page 87: ...4 45 ...

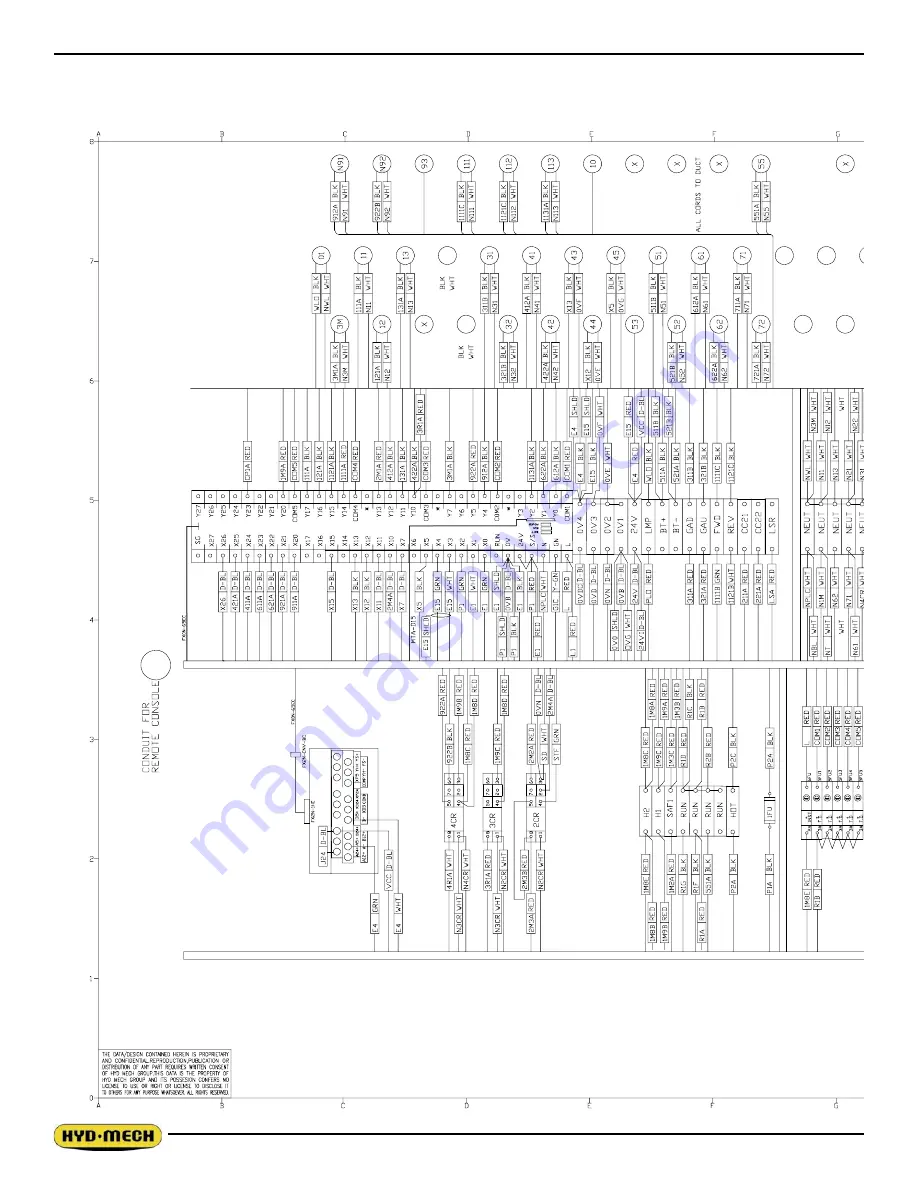

Page 88: ...4 46 V18 APC 480 575 VOLT ELECTRICAL WIRING DIAGRAM ...

Page 89: ...4 47 ...

Page 90: ...4 48 ...

Page 91: ...4 49 ...

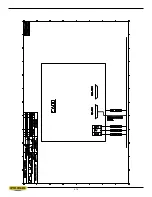

Page 92: ...4 50 V18 APC 480 575 VOLT INPUT AND OUTPUT DEVICES ...

Page 93: ...4 51 ...

Page 94: ...4 52 ...

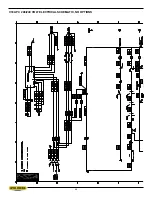

Page 97: ...5 3 V18 APC HYDRAULIC SCHEMATIC ...

Page 98: ...5 4 V18 APC PLUMBING DIAGRAM ...

Page 100: ...6 2 GUIDE ARM ASSEMBLY ...

Page 110: ...6 12 SQUARING VISE ASSEMBLY ...

Page 112: ...6 14 SHUTTLE VISE ASSEMBLY ...

Page 115: ...6 17 COOLANT ASSEMBLY ...

Page 118: ...6 20 CHIP CONVEYOR SHOWN WITH CRANK AND OPTIONAL HYDRAULIC MOTOR ...

Page 124: ...7 4 GUIDE ARM ASSEMBLY FOR EXTENDED HEAD OPTION ...

Page 128: ......

Page 130: ...8 2 ...

Page 131: ...8 3 ...

Page 132: ......