Starting up the unit

FAM 5

en(us)

45 / 100

BEWA FAM5 3667663b en-us 2012-12-12.doc

2012-12-12

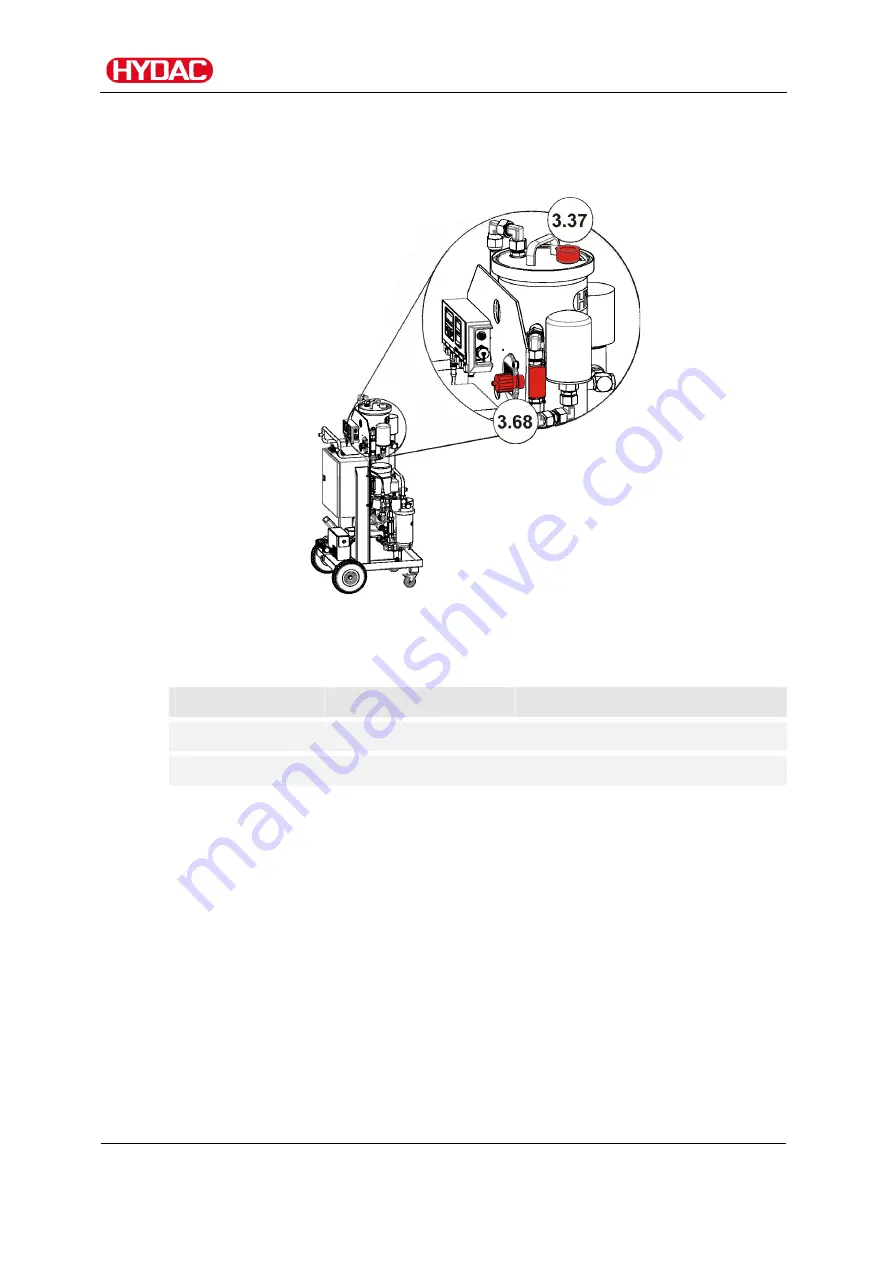

Setting the underpressure in the vacuum column

Use the vacuum gauge (3.68) to set the underpressure in the vacuum

column and check the vacuum on the vacuum pressure gauge (3.37).

Note that the pressure to be set in the vacuum column is dependent on the

operating viscosity, the water content and the air content.

The following settings are guiding values:

Medium

Operating viscosity

Pressure setting

Hydraulic oil

50 mm²/s

-0.6 bar = 400 mbar (absolute)

Lubricant

300 mm²/s

-0.4 bar = 600 mbar (absolute)

Some oils foam intensively when they enter the vacuum chamber. This effect

is particularly pronounced with high water or gas contents. This effect is also

to be observed with older oils or extremely high-viscosity media.

If too much foam is caused, it is drawn in by the vacuum pump. In this case,

reduce the vacuum from -0.6 to -0.4 bar.

Water condensation can also occur in the connecting hose between the

vacuum pump and the vacuum column in the presence of a very high water

content in the oil. The water is separated out into the vacuum pump storage

container. Reduce the vacuum to -0.3 bar in such cases.