6

08/2015

1248867

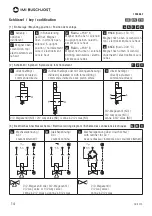

Residual risks

Pressure against valve outlet

Valve only firmly closes in flow

direction.

Fluid freezing

The valve is not designed to

withstand the fluid freezing.

5. Operating conditions

With standard solenoids the maximum permissible

fluid temperatures are limited according to the used

sealing material (see page 8 and 9 for exceptions).

Diaphragm valves:

•

NBR from –10 °C to +90 °C

•

FPM from 0 °C to +110 °C

•

EPDM from –10 °C to +110 °C

Piston valves

•

NBR from –20 °C to +90 °C

•

FPM from –10 °C to +110 °

•

EPDM from –20 °C to +110 °C

•

PTFE from –20 °C to +110 °C

Ambient temperature acc. to

c

CSA

us

certification:

•

solenoids 9100...9149: max. +60 °C

•

solenoids 9150...9199: max. +50 °C

•

solenoids 9300...9399: max. +50 °C

•

solenoids 9400...9499: max. +50 °C

•

solenoids 8170...8199: max. +65 °C

6. Mounting

Only appropriately qualified personnel may install

the valve.

NOTICE

Deposits and dirt lead to malfunctions

If control bores are clogged or core is blocked

by soil the valve no longer closes or opens.

→

Clean the pipe system prior to mounting the

valve.

→

Install a strainer in front of the valve inlet (

P

)

if necessary.

Damage through faulty mounting

Valve only firmly closes in flow direction. Inflow

against the valve’s flow direction may lead to

the destruction of components.

→

Only transport and store valve in its delivery

packaging.

!

CAUTION

Risk of burns at the solenoid

The surface of the solenoid will heat

up to 120 °C during continuous duty.

Touching leads to risk of burns.

→

Leave the solenoid to cool down before

working at the valve.

Residual risks

kg

Weight of the valve

Phases:

transport, storage,

assembly, maintenance, disposal

Risk:

falling off, tipping over

PPE:

protective footwear

Hazardous fluids

Phases:

assembly, operation,

maintenance, disposal

Risk:

skin contact, eye contact,

breathing vapors

PPE:

protective gloves, protective eye

glasses, breathing protection

Sharp threads

Phases:

transport, assembly,

maintenance, disposal

Risk:

risk of cuts

PPE:

protective gloves

Potentially explosive atmosphere

Risk:

danger of explosion

!

WARNING:

Only use solenoids

and device sockets with adequate

Exprotection in areas with explosive

atmosphere.

Damage to property

NOTICE

Disturbance of the solenoid

The application of paint or housing the solenoid

may lead to overheating of the coil and shorten

the solenoid‘s product life cycle.

→

You must not apply paint to the solenoid or

build the solenoid into a heat insulation.

Blocking of internal parts

If the valve is not switched for a long period of

time the internal parts may block.

→

Actuate the valve at least once a week if the

valve gets energized only seldom.