MultiRheo Filter - MRFD3

Safety information and instructions

HYDAC FILTER SYSTEMS GMBH

en(us)

Page 11 / 40

BeWa MRFD3 3217120b en-us 2012-03-07.doc

2012-03-07

Safety measures to be followed in normal operation

Check the product for visible damage and properly functioning safety equipment at

least once a day.

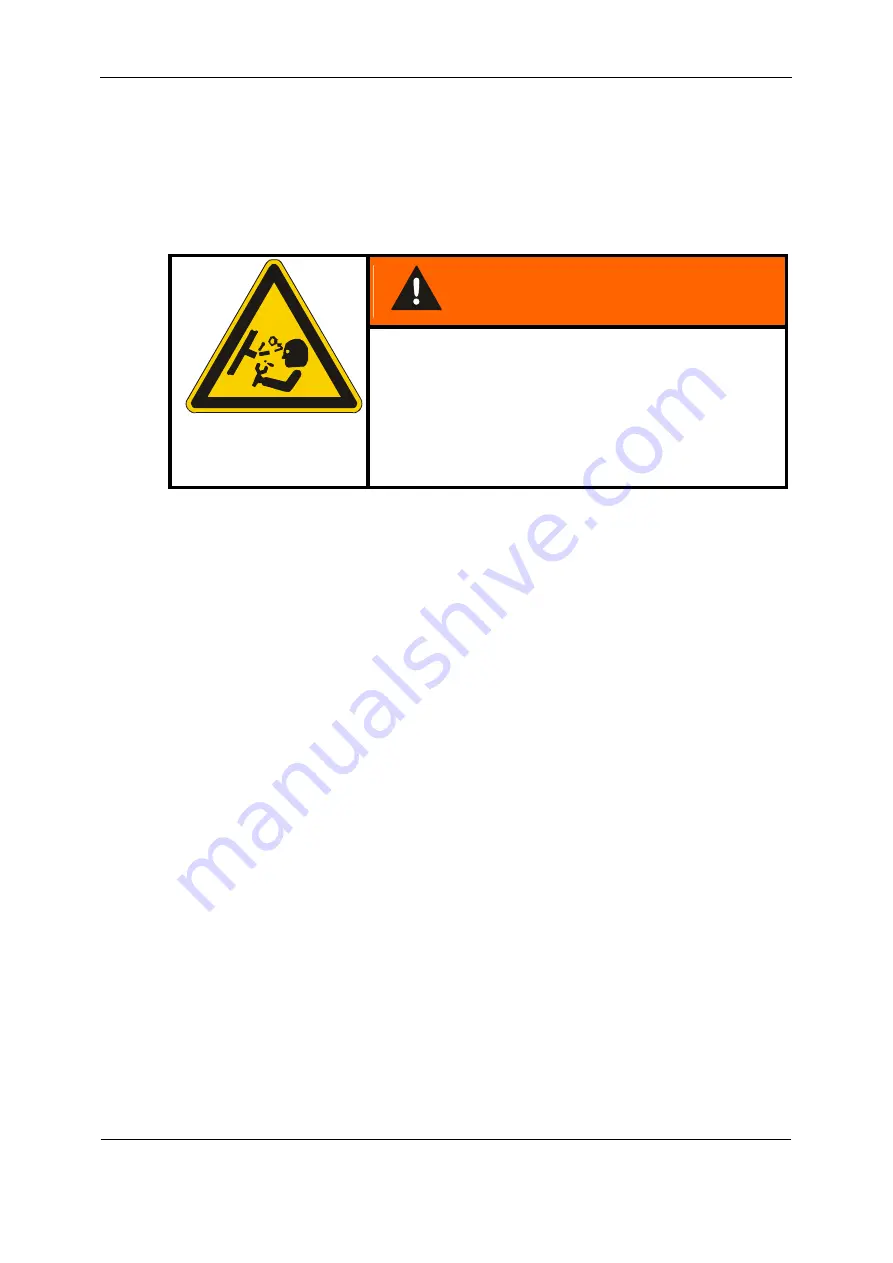

Hazards Posed by Stored Residual Energy

WARNING

Hydraulic systems are under pressure

Danger of bodily injury

►

The hydraulic system must be depressurized

before performing any work on the hydraulic

system.

Note that the unit may pose a hazard as the result of residual stored mechanical

and electrical energy. Take the proper precautions when instructing personnel on

the use of the unit. Detailed information is provided in the respective sections of this

manual.

Modifications to the MRF

Do not make any modifications (design modifications, extensions) to the MRF

without the prior consent of the manufacturer.

Immediately replace any unit components which are not in perfect condition.

Use only original spare parts (OEM). When using non-OEM components it cannot

be ensured that they have been designed and manufactured so as to comply with

loading and safety requirements.