Page 15 of 28 – Operation and Maintenance Instructions for Offline Filtration Trolley OFT20 & OFT-HV

Document No: E1412015-1488-M-02

HYDAC Pty Ltd - 109-111 Dohertys Road, Altona North, Victoria 3025, Australia

Telephone: +61 (03) 9272 8900 ; Fax: +61 (03) 9369 8912 ; Website:

Checking the Scope of Delivery

The filter unit OFT Series is delivered packed and ready for use. Please check the unit

for possible damage before putting it into operation.

Immediately report any damage in transit to the forwarding agent or the HYDAC

department in charge. Do not put the unit into operation.

The following items are supplied:

Item

Qty.

Description

1

1

OFT (Type according to order)

-

1

Operating and Maintenance Instructions (this document)

Technical Description

The application of the OFT Series results in fewer oil changes within the same amount of

time, increases the lifetime of the system filter, the lifetime of the components and the

availability of the machinery.

Restrictions Pertaining to Use

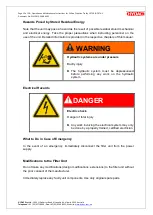

NOTICE

Impermissible operating media

The unit will be destroyed

► The unit is only to be used with mineral oils or mineral oil-based raffinates.

NOTICE

Fluid compatibility

Contamination of system oil

► The unit must be flushed completely and filter element replaced when oil

type, brand or grade is changed.