Connecting the unit

VMU 1 ATEX II 2G IIC T4

en(us)

Page 32 / 60

BEWA VMU _4_ATEX-II2GIICT4_4066057 en-us 2015-10-12.doc

2015-10-12

Make sure that no tension or vibrations are carried over to the pump or filter

housing when the pipes are connected. Use hoses or expansion joints if

necessary.

Connecting the inlet port (IN)

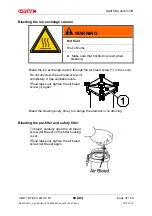

NOTICE

Contamination too high

The unit will be damaged

►

Do not prime directly at the bottom of the tank

►

Do not prime in the sump

►

Never prime without a built-in suction screen

The greatest contamination is found on the bottom of the tank.

All impurities and other particles are deposited on the bottom of

the tank.

The suction pressure at the VMU inlet must be in the range of -0.4 ... 1 bar.

Use a negative pressure-resistant, flexible hose or a pipe for the suction-side

connection.

Make sure that the cross-section of the connected hoses/piping is at least as

large as the cross-section of the inlet/outlet port sizes.

The shape of the tank connection should be set up in such a way that it will

always be lower than the level of the oil in the tank.

Install a shut-off valve on the suction side of the tank.

Summary of Contents for VarnishMitigation Unit

Page 59: ......