HREI

Inst Issue 1: 09.05.16

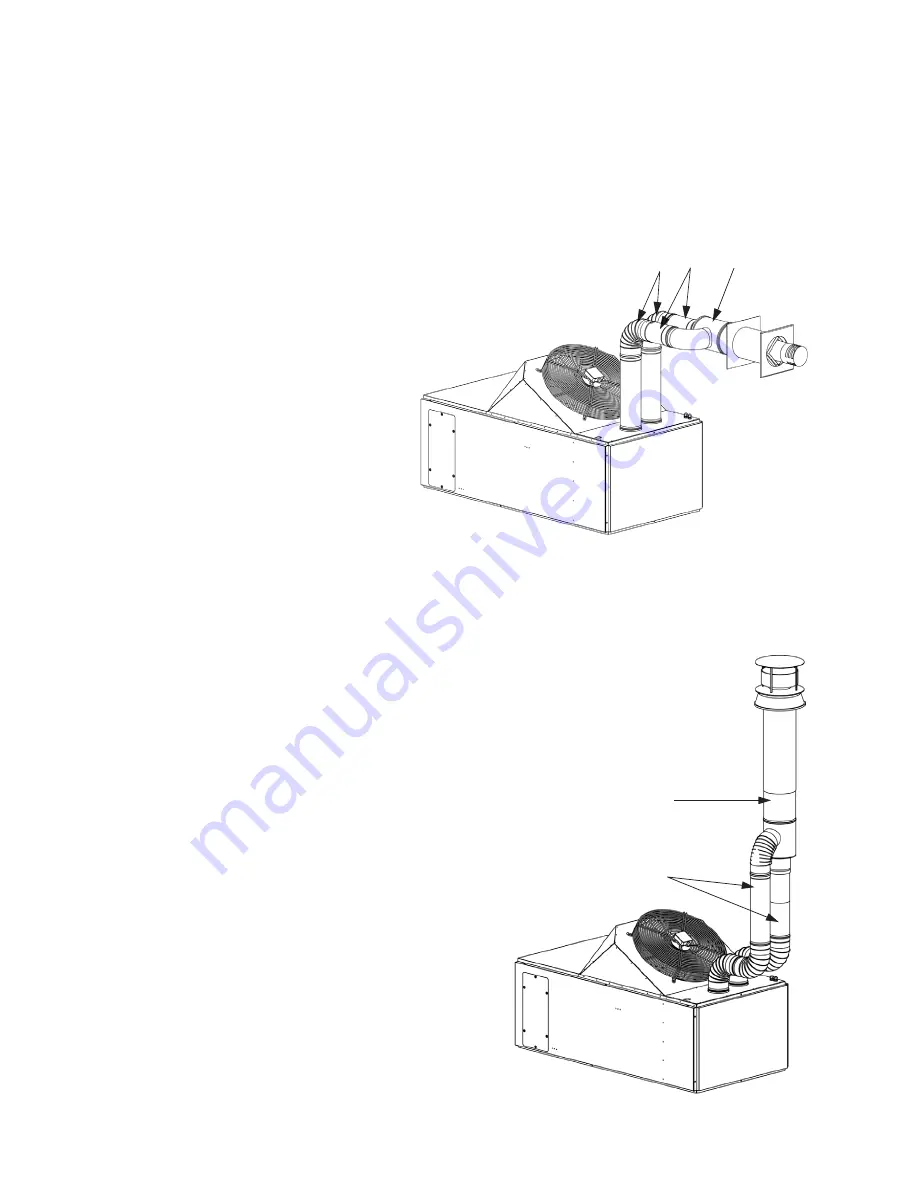

5.3 Concentric Flue Kit Connection. The connection for combustion air intake

and smoke exhaust is made horizontally or vertically towards the outside

of the room.

WARNING

The fumes condensates should not flow inside the unit,

risk of corrosion. If it is needed, foresee a condensate collector. In case

of horizontal concentric installation, foresee a slope of 2° minimum and

opposed to the unit to drain the condensate.

5.4 Mounting type C12: Flue pipe diameter: 130 mm

5.4.1

Two single elbows at 90°

5.4.2

Two single extensions of 1 m

5.4.3

Concentric wall terminal

•

Condensate trap

NOTE

It is possible to

extend or divert the

concentric kit with

approved accessories.

5.5 Roof type C32: Flue pipe diameter: 130 mm

5.5.1

Two single extensions

5.5.2

1 concentric roof terminal

•

Condensate trap

NOTE

It is possible to extend or divert the concentric kit with

approved accessories. The use of flues involves a perfect

sealing. To check the installation, it is necessary to use a

non-aggresive libricant for the gasket, example: soapy water.

NOTE

The junctions must be sealed and rigid. The

section of flue must be at least equal to the diameter

of the heater outlet. The smoke exhaust cannot be

vertical or at 45° minimum. The total length of the

connection cannot exceed 6 m, knowing that:

elbow 90" or 45° = 1 m of flue. If the outside

part of the flue is higher than 2m,

foresee an insulated pipe.

3

2

1

2

1