19

05/05 ID# M866041

Subject to proper installation and normal use, Hydra-Rib

®

warrants, subject to limitations below, to the original retail

purchaser all structural components of the Hydra-Rib

®

system to be free of defects in material and workmanship

for the duration of ownership by the original retail

purchaser.

Mercahndise must be shipped prepaid with a copy of proof

of purchase to our factory for examination to see whether

it needs to be repaired or replaced. Any labor costs,

travel expenses and any other charges involved in the

removal, installation or replacement of the

defective/repaired partsfrom/to your Hydra-Rib

®

system

will be your (the purchaser’s) responsibilty. Shipping

chargesfor replacedor warranted merchandise being

sent back to the customer from our factory must be

prepaid by the customer in advance. If not, the

replacement shipment will be sent out collect.

What is Not Covered By This Warranty

Paint or rusted parts. Paint kits will be available to assist in

normal maintenace.

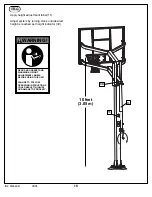

RIM

HANGING ON THE RIM WILL VOID YOUR WARRANTY.

RIms are not warranted for any defects other than

workmanship. Torn back plates, damaged springs, bent

rings, damaged eye bolts, and torn or distorted rim

supports result from hanging on the rim and are not

warranted.

LIMITED LIFETIME WARRANTY