15

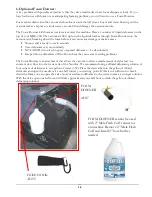

6. Optional Foam Downer:

A key problem with portable extractors is that they have small tanks where foam dissipates slowly. If you

have had issues with foam or are anticipating foaming problems, you will want to use a Foam Downer.

Foam can be drawn into the vacuums before the vacuum shutoff closes. Foam and water blowing out the

vacuum makes a big mess, can decrease vacuum lift and damage the vacuum motors.

The Foam Downer kills foam as waste water enters the machine. Place a container of liquid defoamer on the

top of your MXE-200. The vacuum air flow siphons the liquid defoamer through Foam Downer into the

vacuum tank, breaking down the foam before it can cause any damage or make a mess.

•

Mounts and is ready to use in seconds

•

Uses defoamer very economically

•

NO LABOR is involved to spray or spread defoamer – it’s all automatic

•

Keeps silicone defoamers off the floor where they can cause resoiling problems

The Foam Downer is an attachment that allows the vacuum to draw a small amount of defoamer in a

constant slow flow into the waste tank of the Nautilus. We recommend using a diluted defoaming solution of

four ounces of defoamer to one gallon of water (1-32). Place the draw tube into the gallon of diluted

defoamer and open the needle valve one half turn as your starting point. If this is not sufficient to break

down the foam you can open the valve more or add more defoamer to the water to make a stronger solution.

With the valve open one half turn it will take approximately one half hour to drain the gallon of diluted

defoaming solution.

FOAM

DOWNER

AH17

FOAM DOWNER cannot be used

with 2” Male Flash Cuff connector

on machine. Remove 2” Male Flash

Cuff and install 2” hose barb as

needed.

HOSE HOOK

AH95

Summary of Contents for Nautilus Extreme MXE-200

Page 1: ...1 LMANN20 Revised 02 16 2018 Nautilus MXE 200 Operating Manual EXTREME ...

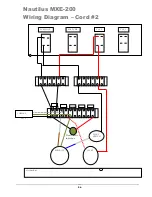

Page 23: ...23 M1200 Wiring Diagram Nautilus MXE 200 Wiring Diagram Cord 1 ...

Page 37: ...37 OPTIONAL AUTO FILL FLOAT VALVE ASSEMBLY NM5740 ...

Page 38: ...38 Pump Out Pump PARTS ASSEMBLY ...

Page 39: ...39 1 4 4 6 7 8 9 10 11 3 3 8 9 12 8 9 39 8 9 2 2 5 ...

Page 49: ...49 92 91 95 94 112 13 14 14A 104 105 1 39 PUMP OUT CONNECTIONS ...

Page 50: ...50 35 36 36A 78 36 36A 34 39 127 128 129 2 1 130 32 34 119 39 131 ...