27

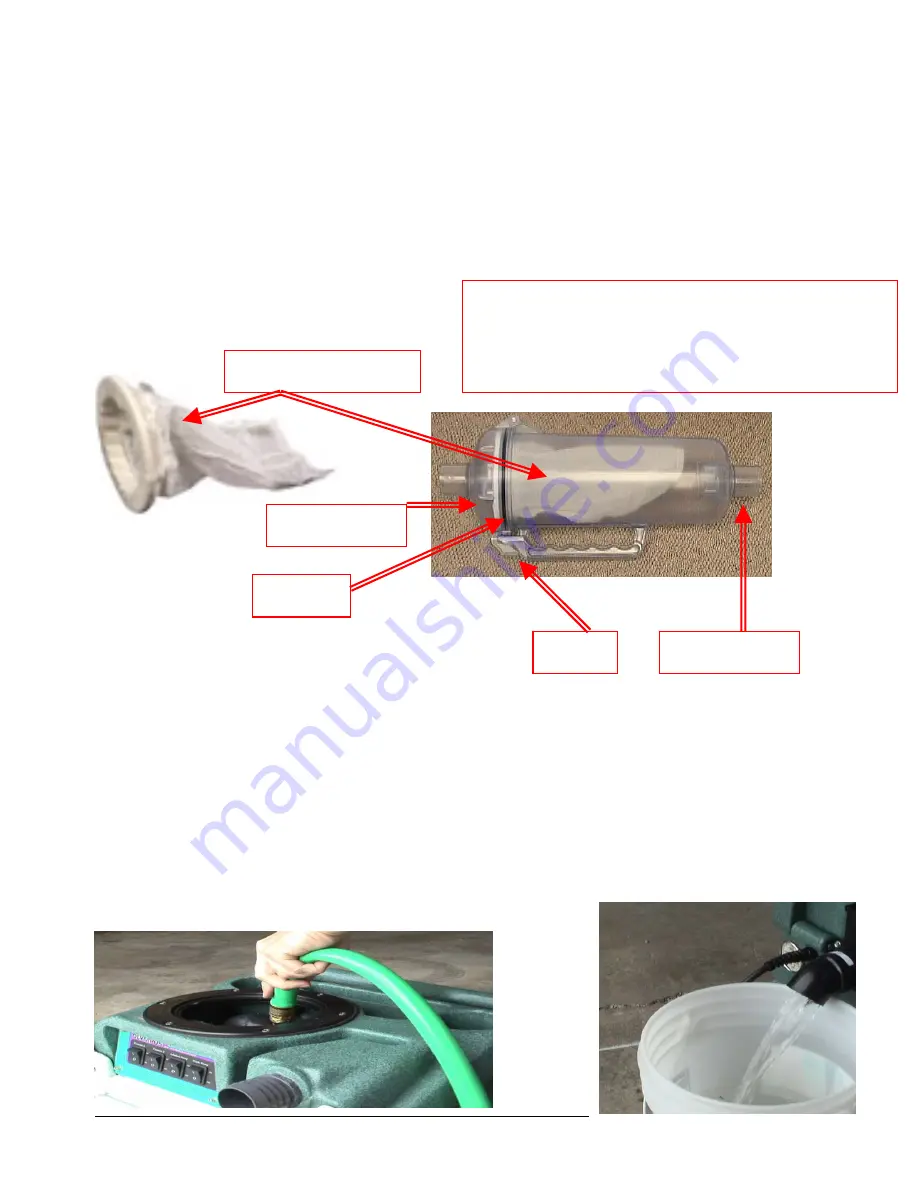

CLEAN THE HYDRO-FILTER: (Optional Accessory)

Build-up of debris in the filter bag of the Hydro-Filter will reduce the vacuum air flow and may cause a

significant decrease in water recovery. A torn filter bag will allow debris past the filter and into the recovery

tank. This debris can clog the Waste Pump and the Vacuum Shutoff Assembly.

The Hydro-Filter must be

examined and cleaned regularly to keep the M3-500 functioning properly:

•

Push the latch lever and open the Hydro-Filter lid.

•

Remove the filter bag. Examine the bag and clean or replace as needed.

•

Rinse the body of the Hydro-Filter with clean water.

•

Examine the o-ring seal and replace as needed.

•

Re-install the new or cleaned bag.

•

Close lid and secure latch.

RINSE OUT RECOVERY TANK:

Build-up of fine silt and debris can damage the Waste Pump and Drain Valve. Clean out the tank on a regular

basis to extend the life of these components as well as keep the tank and machine smelling better.

•

Remove the recovery tank lid and open the drain valve.

•

Place a bucket under the drain valve.

•

Use a hose to rinse the dirt and debris out of the recovery tank.

•

Close the drain valve and spray the tank with a deodorizer or disinfectant.

•

Proceed to Waste Pump Cleaning and replace the recovery tank lid.

•

Dispose of the dirty water and debris.

LID – AC11D

LATCH

O-RING

FILTER BODY

FILTER BAG – AC11A

Repair parts are available for the Hydro-Filter:

Filter Bag: AC11A

Parts Kit: AC11B – (Includes Latch, O-ring & screws.)

Lid:

AC11D