25

PC Series

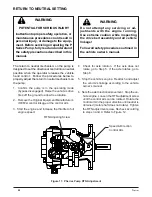

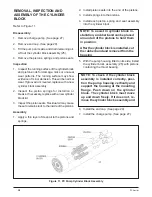

Refer to Figure 4.

Disassembly

1. Remove retaining ring (22) from housing.

2. Remove lip seal (20). Care must be taken to

prevent damage to the housing bore, shaft

sealing surface, or bearing. Once removed, the

seal is not reusable.

Inspection

With seal removed inspect the spacer (21) and

housing (1) bore for damage, corrosion or wear.

Assembly

1. Lubricate the new lip seal (20) inside diameter

with petroleum jelly.

2. Wrap the input shaft (18) with plastic wrap to

prevent damage to the inner surface of the lip

seal (20).

3. Slide spacer (21) and seal (20) over shaft (18)

so that lettering on the seal faces out.

4. Press the lip seal (20) into the housing bore.

Insure the lip seal (20), shaft (18) or housing

(1) bore do not become damaged. Remove the

plastic wrap.

5. Install the retaining ring (22) into the housing

(1) bore groove. Refer to Figure 4.

REMOVAL, INSPECTION AND/OR

REPLACEMENT OF INPUT SHAFT

SEAL

Figure 4. PC Pump Input Shaft Seal

REMOVAL, INSPECTION AND/OR

REPLACEMENT OF TRUNNION

ARM SEAL

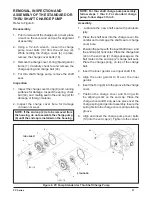

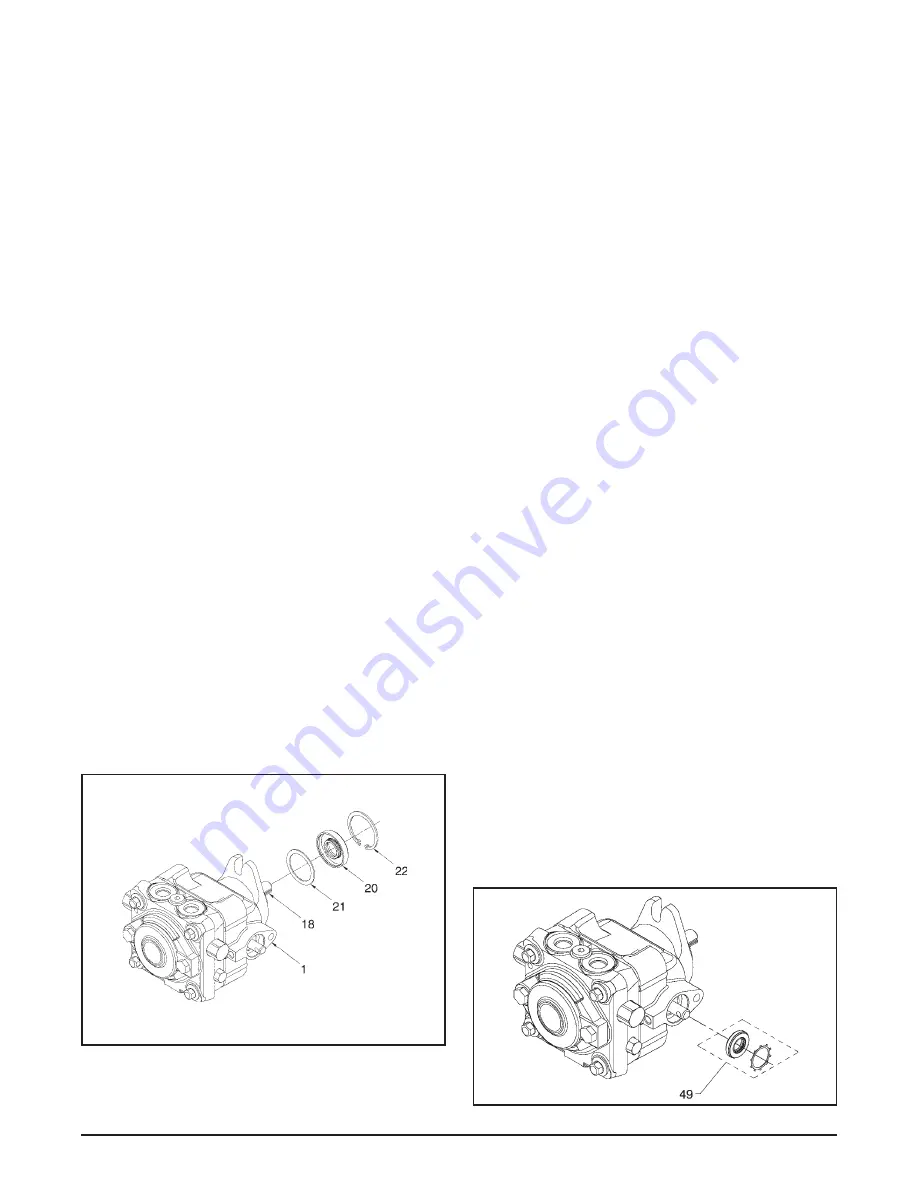

Figure 5. Trunnion Arm Seal

Refer to Figure 5.

Disassembly

1. Remove the RTN assembly or control arm.

2. Remove the retainer and lip seal (49) from the

housing. Care must be taken to prevent damage

to the housing trunnion bore, trunnion arm and

sealing surface. Once removed the retainer and

lip seal are not reusable.

Inspection

With the lip seal (49) removed, inspect the area for

corrosion and wear. Inspect the trunnion bore area

sealing surface for damage or wear.

Assembly

1. Lubricate the new lip seal (49) inside diameter

with petroleum jelly.

2. Wrap the trunnion arm with plastic wrap to

prevent damage to the inner surface of the lip

seal (49).

3. Slide the lip seal (49) over the trunnion arm so

that the lettering on the seal (49) faces out.

4. Press the lip seal (49) into the housing bore.

Insure the seal (49), trunnion arm, and housing

bore do not become damaged. Remove plastic

wrap.

5. Install the retainer from (49) over the trunnion

arm on top of the lip seal. Press into the trunnion

seal bore in the housing until the retainer mates

against the trunnion seal.

6. Install the RTN assembly or control arm.

Summary of Contents for HGM-H Series

Page 1: ...BLN 0043 January 2018 HGM H Series Motor Service and Repair Manual ...

Page 25: ...24 HGM H HGM H MOTOR EXPLODED VIEW ...

Page 29: ...HEMTM Series Motor Service and Repair Manual BLN 0083 January 2018 ...

Page 52: ...PRM MOTOR Service and Repair Manual ...

Page 56: ...PRM 3 EXTERNAL FEATURES PRM MOTOR Figure 1 PRM External Features ...

Page 77: ...24 PRM SECTION 8 PARTS LIST Figure 48 MA04K030 ...

Page 81: ...BLN 50231 January 2018 BDP 10L PL Hydrostatic Pump Service and Repair Manual ...

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ...HGM 12P LSHT Wheel Motor Service and Repair Manual BLN 52197 January 2018 ...

Page 102: ...2 Exploded view HGM P ...

Page 117: ...HGM E LSHT Wheel Motor Service and Repair Manual BLN 52198 January 2018 ...

Page 144: ...2 P Series EXTERNAL FEATURES PC SERIES Figure 1 PC Pump with Standard Charge Pump ...

Page 146: ...4 P Series EXTERNAL FEATURES PJ SERIES Figure 3 PJ Pump with Standard Charge Pump ...

Page 147: ...5 P Series Figure 4 PK Pump With Standard Charge Pump EXTERNAL FEATURES PK SERIES ...

Page 176: ...34 PC Series Figure 16 PC Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 192: ...52 PG PE Series Figure 17 PG PE Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 208: ...70 PJ Series Figure 17 PJ Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 224: ...88 PK Series Figure 17 PK Pump BOXES INDICATE ITEMS INCLUDED IN Kit Number ...

Page 240: ...106 PR Series Figure 17 PR Pump BOXES INDICATE ITEMS INCLUDED IN KITS Kit Number ...

Page 261: ...HGM C LSHT Wheel Motor Service and Repair Manual BLN 52690 January 2018 ...