34

ZT-2800

®

/ZT-3100™/ZT-3400™

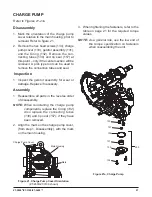

figure 30, Center section Kit (201)

CenTer seCTiOn KiT

Refer to Figure 30

disassembly

1. Remove the bypass plate (22) from the

center section.

2. Remove the plug seals (26) and discard.

Refer to figure 31, on page 35.

IMPORTANT:

Before removing the check

plugs, it is important to note their specific loca-

tion, i.e., check plug (24) needs to be reinstalled

in the same port it was removed from and the

same for check plug (25). After removing the

check plugs, inspect for debris or damage.

3. Remove the check plugs (24) and (25) and

inspect. Refer to Check Plugs & Seals, page

35.

— Charge Relief Kit —

4. Remove the pin, spring and ball that make

up the charge relief kit (202). Depressing

the charge spring with the (clean) flat side

of a slotted screw driver will allow the pin

to slide out. Use caution when relieving

spring force. Inspect the center section at

the charge seat for wear or damage.

NOTE:

The check ball should seat properly in

the check seat.

inspection

1. Inspect all components for unusual wear or

damage. Pay particular attention to the cen-

ter section’s threaded ports and passages;

there must be no lose particles or debris.

assembly

1. Install the charge relief kit (202). Beginning

with the ball, then the spring, followed by,

the cross pin.

2. Install the new check plugs (24) and (25) in

their proper ports.

3. Install the new plug seals (26).

4. Install the bypass plate (22). Applying a very

small film of grease on the bypass plate, will

help secure it in the center section.

Center section — non-Charge

NOTE:

For non-charge ZT-2800 units without

“charge relief,” a rubber plug (16) will be

present rather than connecting tubes (ref.

on page 27, Figure 21a). See diagram to

the right.

26

25

22

24

Charge

Relief Kit

(202)

Center Section

Rubber Plug (16)

Solid