ORBIT

®

SPRINKLER SySTEm DESIGNER™

InstallatIon GuIde

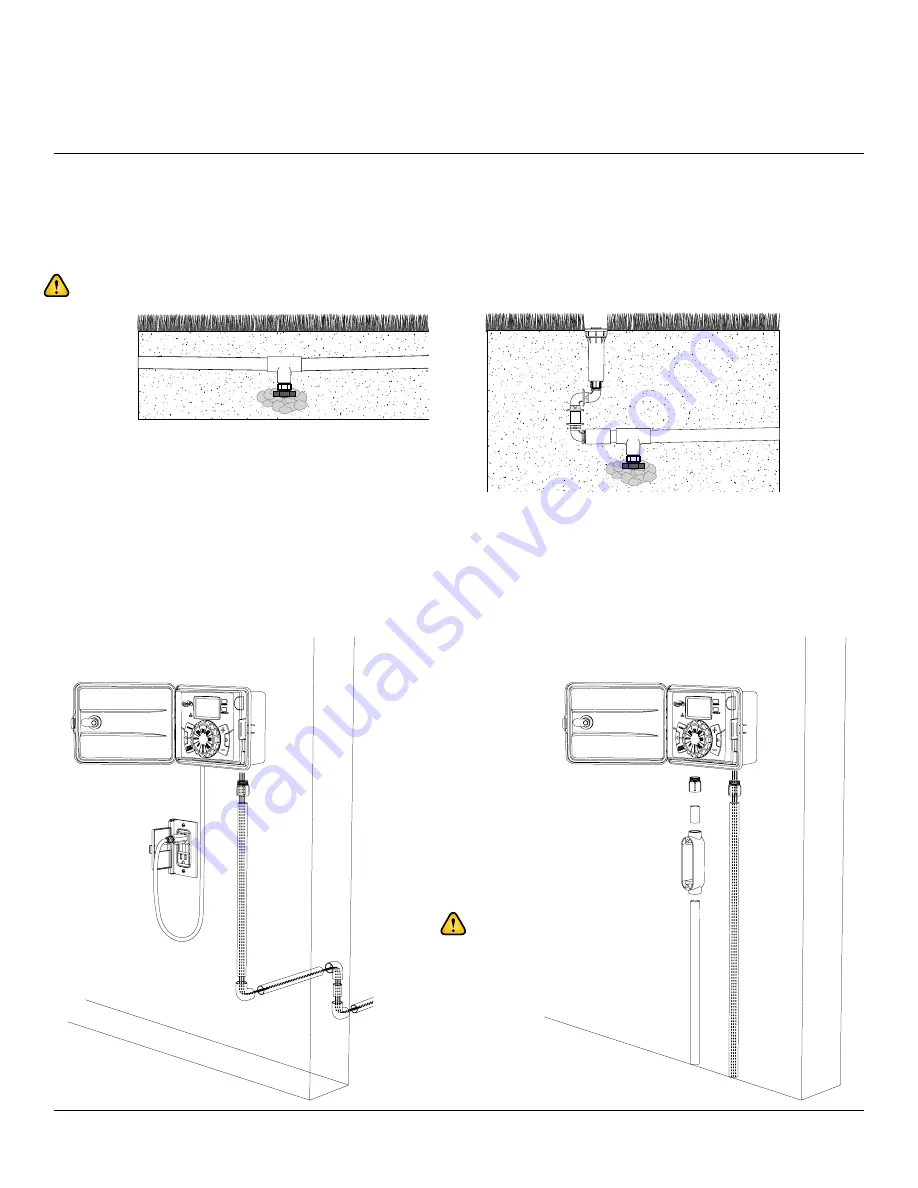

11. Install auto-dRaIns (fReezInG aReas onlY)

Where freezing is a concern we recommend you install auto-drain valves at the low spots in the system

and on the downhill ends of sloping pipes. The auto drains must be at the lowest points in the line.

The timer provided can be mounted indoor or outdoor. For indoor installation refer to the diagram below

and the next page. For outdoor installation use a licensed professional electrician.

outdooR InstallatIon

exterior Wall

exterior Wall

IndooR InstallatIon

a

sprinkler Wire

B

1/2" Conduit nipple

C

Conduit

d

Junction Box

e

Elbow

Use a licensed

professional electrician

for outdoor installations.

a

B

C

C

e

a

B

B

C

C

C

d

Do Not install auto-drains on the Poly mainline

12. INSTALL THE TIMER