22

Page

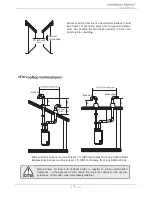

-Measuring inlet gas pressure-

The micro-boiler cannot perform properly without su

fficie

nt inlet gas pressure. Below are ins

tructions

on

how to check the inlet gas pressure.

THIS IS ONLY TO BE DONE BY A LICENSED PROFESSIONAL

.

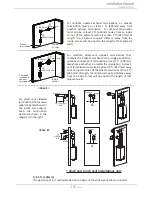

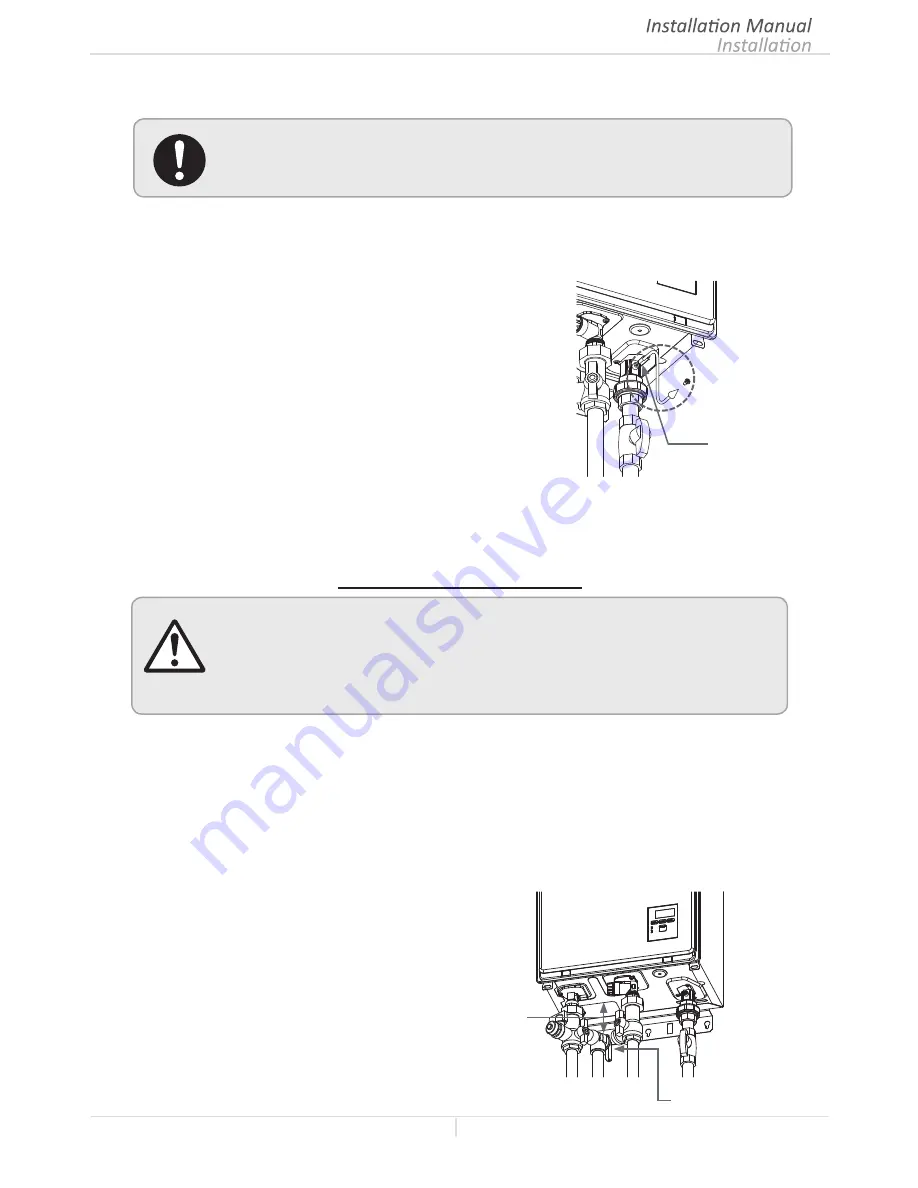

WATER CONNECTIONS

All pipes, pipe

fittings,

valves and other components, including soldering materials, must be suitable for

space heating

systems.

1.

A manual shuto

ff

valve must be installed on the cold water inlet to the micro-boiler between the main

water supply line and the micro-boiler.

2.

In

addition,

a manual shuto

ff

valve is also recommended on the hot water outlet of the micro-boiler.

If the micro-boiler is installed within, or subjected to, a closed loop water system, a thermal expansion

tank or code approved device to handle thermal expansion must be installed. We recommend isola

tion

valve sets with hose bibs for serviceability such as

flushi

ng. See maintenance and service

section

.

1. Turn o

ff

all electric power to the micro-boiler if service is to be performed.

2. Turn the manual gas valve located on the outside of the micro-boiler clockwise

to the o

ff

posi

tion

.

•

Do not use this micro-boiler if any part has been submersed under water.

Immediately call a licensed professional to inspect the micro-boiler to replace

any damaged parts.

•

Do not reverse the hot outlet and cold inlet c

onnectio

ns to the micro-boiler.

This will not properly

acti

vate the micro-boiler.

CAUTION

1. Shut o

ff

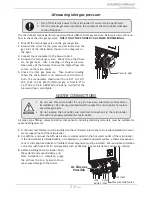

the manual gas valve on the gas supply line.

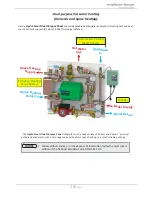

2. Remove the screw for the pressure port located on the

gas inlet of the micro-boiler shown in the diagram on

the right.

3. Connect the manometer to the pressure port.

4. Re-open the manual gas valve. Check to see that there

are no gas leaks. Take a reading of the gas pressure.

Open some of the

fi

xtures that use the highest

fl

ow rate

to turn on the micro-boiler.

5. Check the inlet gas pressure. Take another reading.

When the micro-boiler is on maximum and minimum

burn, the manometer should read from 5.0” to 10.5”

W.C. (1.24 to 2.61 kPa) for Natural gas, or from 8.0” to

14.0” W.C. (1.99 to 3.48 kPa) for Propane. Verify that the

pressure drop is acceptable.

3.

Before installing the micro-boiler,

flush

the system to remove all debris, and

a

ft

er installa

tion

is complete, purge

the air from the line. Failure to do so

may cause damage to the boiler.

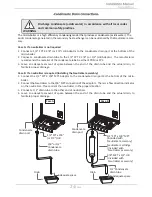

Cold

inlet

Hot

outlet

Gas inlet

As Close as

Possible

Pressure relief valve

Pressure port

Summary of Contents for HS120CON-LP

Page 27: ......