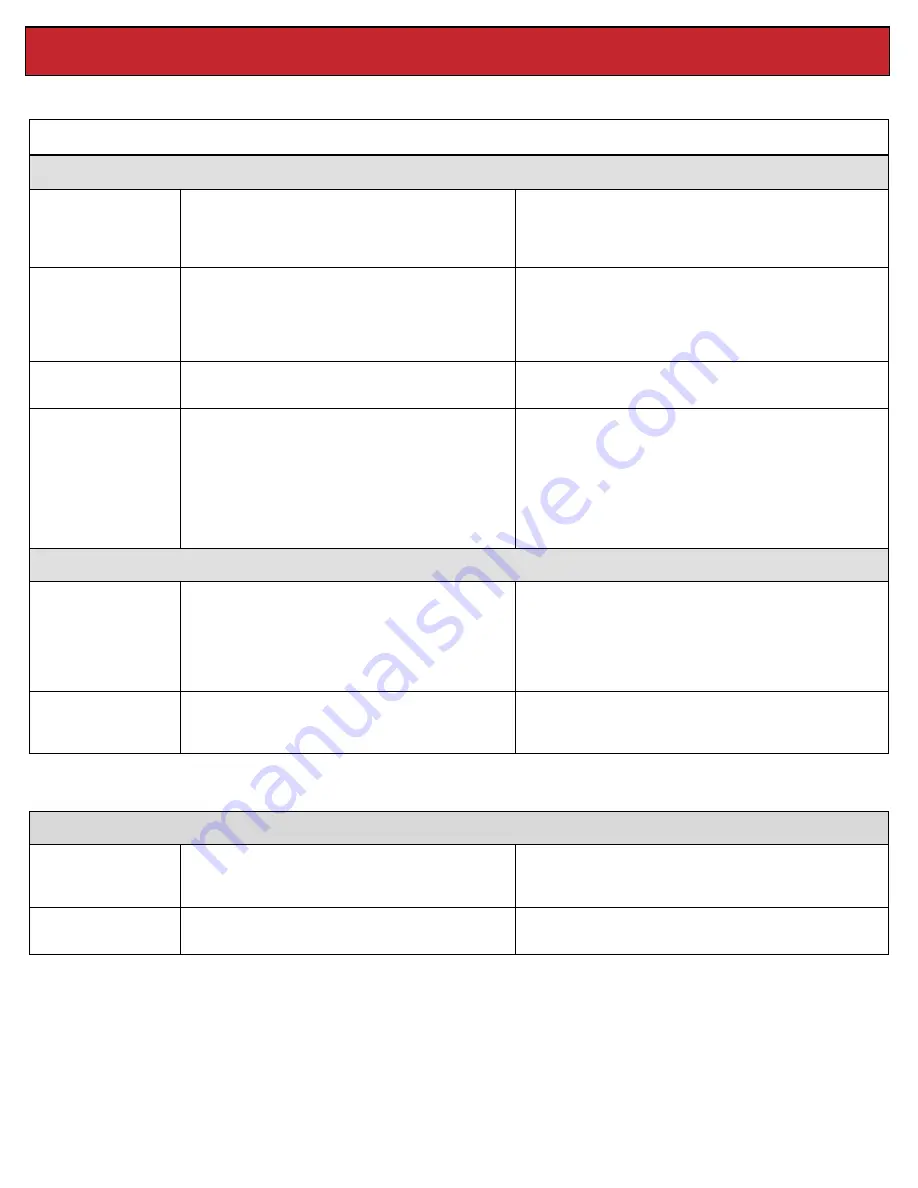

PROBLEM

PROBABLE CAUSE

(The most recurring probable cause is listed first)

REMEDY

(Repairs should only be made by a qualified technician)

Power System: Gasoline or Diesel Engine Powered

Engine will not start or crank

over

Battery dead.

Dirty battery connection.

Battery cables disconnected.

Engine, pump, or gearbox is seized.

Key-switch, solenoid and starter on engine defective

Charge or replace battery, add electrolyte if battery is new.

Clean connections / Carefully check polarity.

Connect or replace damaged cables.

Replace or repair seized part.

Repair or replace.

Engine will not start but will

crank over

Engine power switch is off or defective.

Low oil shut down is activated.

Low water switch engaged or defective (not on all models).

Low on fuel.

Fuel filter is clogged.

Engine flooded or starved.

Check engine power switch.

Add oil to engine, check more frequently.

Add water to bulk tank feeding pressure washer.

Fill with appropriate fuel, bleed injector pump on diesel engine.

Replace or clean fuel filter

Choke only as required.

Engine bogs down under load

whenever spray gun is

triggered

Engine needs to be repaired or replaced.

Operating in high elevation.

Carbon deposits on cylinder head

See engine manual or engine dealer.

Lower the pressure on the unit and check for correct engine speed (RPM).

Remove head and wire brush deposits.

Battery keeps losing voltage

(For 12v systems)

Battery voltage low.

RPM too low.

Engine charging system faulty.

Electrodes misadjusted.

Fuel pump pressure too high. Air band too far open.

Burner amp draw too high.

Have battery checked and load test, charge if low and replace if necessary.

Allow water to cool 2 minutes before shutting off engine.

Engine RPM should be 3600 RPM with no load.

Check engine charging system – must have 10 to 25 amp output.

Adjust electrodes to maximum 1/8” gap.

Fuel pump pressure should be approximately 125 to 160 psi. Adjust for

proper burn.

Check amp draw of burner motor – should be 11 amp or less. Check amp

draw of transformer – should be 4.8 or less.

Power System: Electric Motor Powered

Electric motor does not start No electric power.

Thermal overload in the motor or starter has been tripped.

Power switch inoperative.

Electric motor or wiring failure.

No water to inlet.

Check cord, plug, socket, and breaker. Check voltage.

Reset manual overload by depressing the thermal switch on the outside of

the motor or starter after the motor has cooled. CAUTION! Automatic

overload will restart the motor automatically when it has cooled.

Check power switch.

Replace or repair motor and/or wiring.

Connect water supply.

Machine will not auto-start (if

equipped with ETS or ITS)

Must have adequate water supply.

Scale build-up in coil.

Check filter screen & inlet pressure.

Inlet flow switch defective / jammed with debris.

25 PSI minimum.

De-scale coil for better water flow.

Remove spray nozzle and pull trigger to check auto-start function.

Check mechanical function & electrical signal to relay.

Water Temperature

Discharge water temperature

exceeds recommended

operating temperature

Burner input too high for conditions.

Water flow restricted.

High temperature limit switch faulty or set too high.

Decrease fuel pump pressure and/or fuel nozzle size.

Clean or replace nozzle of proper size. De-scale coil and clear

obstructions.

Replace or reset temperature limit switch.

Discharge water temperature

not reaching maximum

operating temperature

Burner input too low for conditions.

Increase fuel pump pressure and/or fuel nozzle size.

TROUBLESHOOTING GUIDE

14