12

13

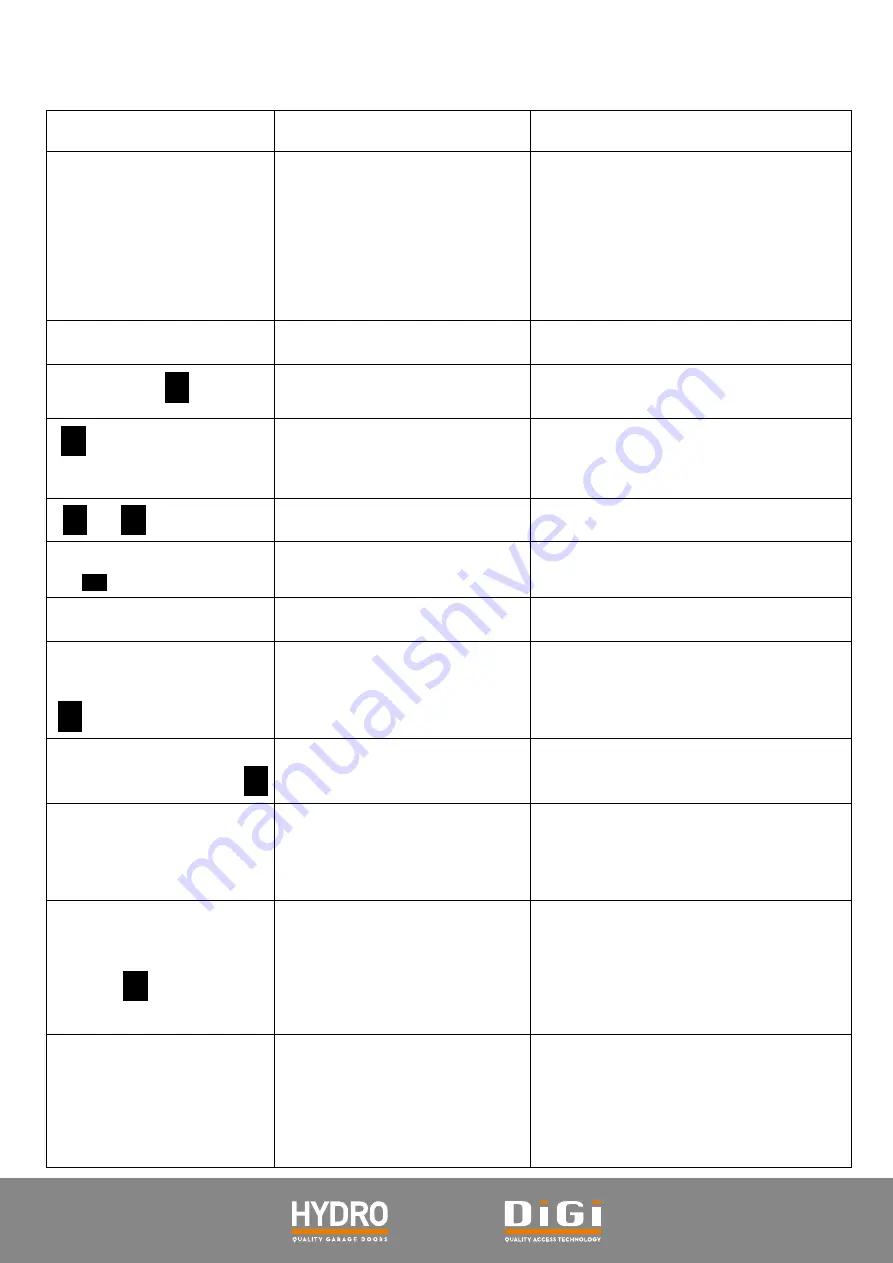

COMMON FAULTS & SOLUTIONS

Nature of Fault

Possible Cause

Solutions

Operator not functioning.

LCD screen is dim.

1. No power supply.

2. Plug wire is loose.

1. Check that mains voltage is present.

2. Check the fuse.

3. Check the low-voltage wires from the

transformer to the control board.

4. Check that the ribbon cable is plugged

into the board.

5. If 26V AC is present on the transformer

low-voltage side, replace the control

board. If not, replace the transformer.

Loss of Limit settings

System error

Reset the limits. (See

PROGRAMMING

OPEN AND CLOSE LIMITS

.)

While learning, is

displayed.

Travel is less than 30cm or more

than 9m.

Reset the limits. (See

PROGRAMMING

OPEN AND CLOSE LIMITS

.

)

is displayed, and the

operator does not work or

stops working.

Insufficient voltage.

Check the power supply.

or is displayed.

Unbalanced springing of the door. Adjust the spring system of the door to

achieve balance.

The operator is not working

and is displayed

Open and close limits failed to

learn, or improperly learnt.

Reset the limits. (See

PROGRAMMING

OPEN AND CLOSE LIMITS

.)

Curtesy LEDs are always on.

Either the control board or the

power supply board is faulty.

Replace the control board or power board.

After starting the door, the

operator stops automatically

after running 10cm, and

is displayed.

Hall sensor wire is loose or

damaged.

Open the cover, check the hall sensor wire,

and re-plug or replace.

Operator does not work. The

relay is heard to ‘click’, and

is displayed

The wires between the gear

motor and the control board may

be loose.

Open the cover and check the wires

between the gear motor and the board.

Operator stops automatically

after running 10cm, nothing is

displayed.

The wires between the gear

motor and the board are plugged

in inversely.

First power off. Open the cover and

reverse the plug on the wires between the

gear motor and the board. Reset the limits.

(See

PROGRAMMING OPEN AND CLOSE

LIMITS.

)

The door opens, but will not

close and is displayed.

1. If no Safety Beam device is

installed:

2. If a Safety Beam device is

installed:

1. Disable the Safety Beam function if no

safety beam device is connected.

(See

PROGRAMMING INSTRUCTIONS:

SAFETY BEAM

.)

2. The Safety Beam may be faulty,

incorrectly connected, misaligned or

obstructed by some object.

After being open for some

time, the door closes by itself.

The courtesy LED lights flash

4 times.

Automatic closing function is

selected

Disable the Auto Close function or, if

required, set a more suitable delay.

NOTE:

It is highly recommended that a Safety

Beam device is fitted if Auto Close is

selected.

(See

PROGRAMMING INSTRUCTIONS:

AUTOMATIC CLOSING.

)

-

H

r

H

L

P

b

O