Page 23

Hydro Systems Europe 2018

10. troubleshooting

CAUTION

Before any fault finding/troubleshooting, isolate the incoming power source and disconnect. All trigger signals

should also be isolated.

Issues listed here are to be investigated and resolved by a competent engineer.

Any fault conditions not listed within this manual should not be attempted to be fixed/replaced without the advice of Hydro

Systems Europe (Any unauthorised attempts to repair the unit will invalidate the warranty).

Issue

Potential Issue

Resolution

Unit will not draw chemical

Low water pressure

Check water line. Booster pump may be

required

Pick up tube not in chemical

Ensure pick up assembly is correct.

Eductor blocked

Remove & clean in warm water

Solenoid valve faulty

Blockage in chemical pickup

Remove, clean and replace.

Unit will not power up

No power to the unit

Faulty PCB

Check power supply

Check fuses

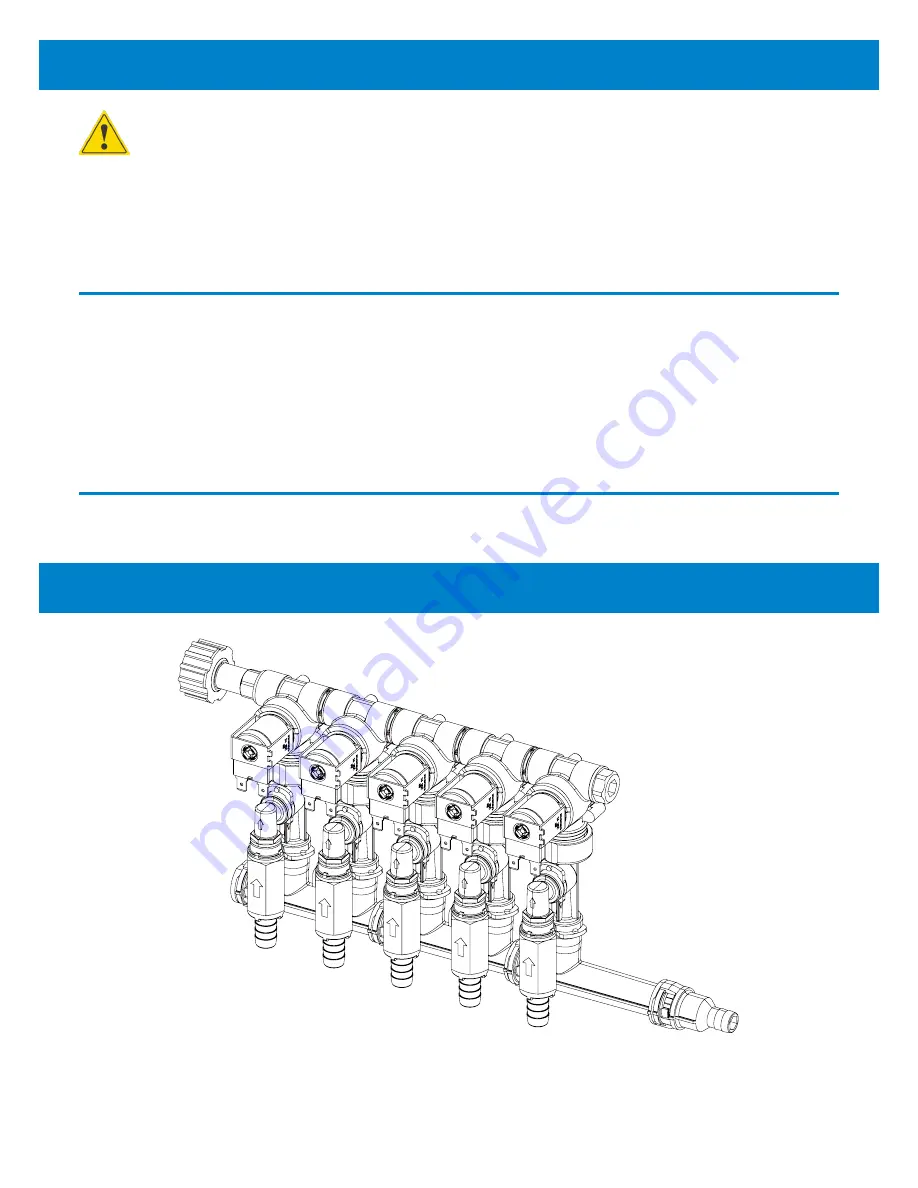

11. unit diagram & replacement parts