Page 36

»

Clean both strainer.

»

Check the base and its connections

for limescale deposits and clean if

necessary.

»

Insert a new O-ring in the base.

»

Insert new O-rings between the cyl-

inder halves and in the steam hose

adapter.

»

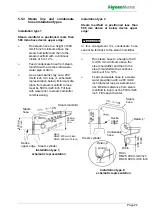

Put the cylinder halves together and

reconnect them with the flange

clamps.

»

When assembling the cylinder, make

sure that the brackets and reinforce-

ments are on top of each other.

Risk of functional disruption!

Use descaler or cleaning detergents only for

cylinder and heater element cleaning. Do not

introduce in cylinder base or apply to hoses!

Prior to restarting the unit, make sure that the

device assemblies in question are thoroughly

flushed or rinsed.

Possible damage to the unit!

Excessive use of force during mechanical

cleaning of the cylinder or heating element

can damage these parts of the unit.

9.5.3 Cleaning the connecting hoses,

base connections, fine filter

and drain pump

»

Check the connection hoses for con-

dition and free passage.

»

Check all connections of the cylinder

base for free passage.

»

Clean the hoses and connections if

necessary.

»

Remove the fine filter on the water

connection side from the solenoid

valve and clean it under running

water.

»

Clean the drain pump as described

in the section of the same name.

When operating with partially softened water

or tap water, scale may be discharged with

the steam flow and may settle in the nozzle

positioned in steam hose adapter. Therefore,

this nozzle should be inspected regularly as

part of the general maintenance review and

cleaned if necessary.

NOTICE

NOTICE

NOTICE

Summary of Contents for FlexLine FLH03

Page 1: ...FlexLine Electric Heater Steam Humidifiers ÁFLH ENKÈ FLH EN E 8881164 Manual ...

Page 45: ...Page 45 11 Declaration of Conformity ...

Page 49: ...Page 49 This page intentionally left blank ...

Page 50: ...Page 50 This page intentionally left blank ...