Page 33

9.3 Maintenance frame work

when unit is operated with

fully demin. water and con-

densate

Instructions on maintenance and cleaning

intervals are entirely based on empirical data.

9.4 Maintenance when unit is

operated with tap water or

partially softened water

No precise maintenance intervals can be

specified because these always depend on

water quality and the amount of steam gener-

ated. It is advisable to adjust the frequency of

maintenance to the specific operational expe-

rience. HygroMatik recommends to check the

opened steam cylinder 1 or 2 weeks after ini-

tial commissioning in order to quantify the

amount of residue produced so far, allowing

for determining future maintenance intervals

and/or the adjustment of blow-down cycles

possibly required.

Blow-down cycles

The vaporisation process causes hardness

builders (calcium) in form of solids of various

compositions to fall out within the steam cylin-

der. Cyclic blow-down by means of a powerful

blow-down pump followed by fresh water

refills remove parts of this solid built-up.

Water quality

When tap water is used, it must be taken into

account that cleaning intervals shorten as the

carbonate hardness level increases. As a

general rule, it is preferable to operate the unit

with fully demineralized water since ope-

ration will not be affected by mineral deposits

and flushing loss will be minimized.

Possibly, maintenance intervals may be

extended by moderately increasing the blow-

down cycle rate. Please consult your expert

dealer.

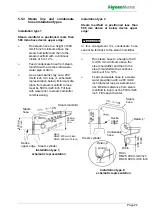

Cycle time

Maintenance work

4 weeks after

commissioning

(also after installa-

tion of a new steam

cylinder)

•

Visual inspection of electrical and mechanical connections

•

Remove mineral deposits from steam cylinder, water drain hose

and blow-down pump

•

Visual inspection of level control.

•

Visual inspection of the steam cylinder interior.

annually

•

Visual inspection of electrical and mechanical connections

•

Remove mineral deposits from steam cylinder, water drain hose

and blow-down pump.

•

Visual inspection of level control.

•

Visual inspection of the steam cylinder interior.

•

Removal of used O-rings between the cylinder halves, in the base

and in the steam hose adapter

•

Cleaning the vent hole in the pipe bend

•

Cleaning the fine filter of the solenoid valve

•

Checking the hoses

Please note

Summary of Contents for FlexLine FLH03

Page 1: ...FlexLine Electric Heater Steam Humidifiers ÁFLH ENKÈ FLH EN E 8881164 Manual ...

Page 45: ...Page 45 11 Declaration of Conformity ...

Page 49: ...Page 49 This page intentionally left blank ...

Page 50: ...Page 50 This page intentionally left blank ...