MaxiCut 5-60 USER MANUAL EDITION 2-05 2012-10-23

7

4. Machine

4.1 Identification

The information for identifying the machine is found on the plates, located out

-

side of the cutting machine. This essentially includes:

• Manufacturer • Serial number • Year of manufacture • Voltage (V)

• Hertz (Hz) • Amperes (A) • Weight

The CE- approval plate is located at the back of the machine, on the top to the

right.

note !

It is strictly forbidden to remove or damage the plate. should this happend,

always contact an authorized techical service only.

For any information and/or technical explanations regarding the cutting machine,

always indicate:

• Model • Serial number • Edition and preparation date of the instruction manual

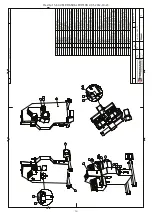

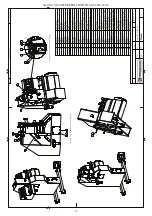

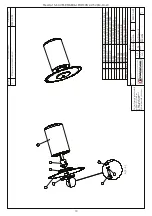

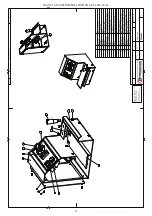

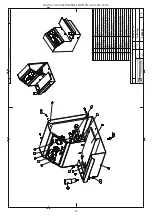

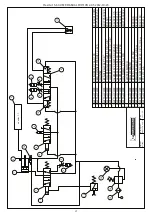

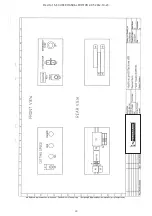

4.2 Description

The stationary hose cutting machine consists of one unit, equipped with a pneu

-

matic cylinder, which is manouvered by a foot pedal and flap doors that are press

-

sed down by the hose during the cutting process. The unit is also equipped with

a connection for a smoke evacuator (option), and as standard a toothed cutting

blade assembled on the machine.

The machine is equipped with an air pressure regulator and filter. Do not start the

machine before the air pressure has reached min. 5 bar.

The hose cutting machine must only be used for hydraulic hoses compatible with

the specifications below. Follow the environmental conditions and limitations

recommended by Hydroscand Machine AB and current health and safety regula

-

tions.

note !

the descriptions includes the use for which the machine has been designed,

built and protected. Any other use or failure to comply with the technical

parameters listed below, may constitute a hazard to people and/or property.

Summary of Contents for MaxiCut 5-60

Page 1: ...UseR MAnUAL edition 2 05 2012 10 23 serial number MaxiCut 5 60...

Page 14: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 14...

Page 15: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 15...

Page 16: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 16...

Page 17: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 17...

Page 18: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 18...

Page 19: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 19...

Page 20: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 20...

Page 21: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 21...

Page 22: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 22...

Page 23: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 23...

Page 24: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 24...

Page 25: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 25...

Page 26: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 26...

Page 27: ...MaxiCut 5 60 USER MANUAL EDITION 2 05 2012 10 23 27...