Page 10

PowerCut 5-85OT USER MANUAL EDITION II 2017-09-08

6. Maintenance

WARnInG!

When doing maintenance on the machine do always make sure that the machine is unplugged from

the electrical net, pneumatic and do always press down the emergency switch. Taking these safety

measurements ensures that no electrical tension is supplied to the machine that could make it start.

Do always use protecting gloves when changing cutting blade. Do always use protective clothing and

protective shoes to make certain that no injuries will happen if dropping the cutting blade on the

body or feet.

6.1 Replacing the cutting blade

1.

Unplug the machine and press down the emergency switch.

2.

Open the lid on the left side of the machine stand and

open the front hatch.

3.

Loosen the socket set screws and the socket head cap screws,

outer carrier behind the lid.

4.

Dismantle the old blade and assemble a new one. Only use by

hydroscand Machine recommended cutting blades.

5.

Assemble the centre socket head screw tightly;

torque 80 Nm. Tighten the two socket set screws to

secure the cutting blade.

6.

Reassemble the lid and the front hatch. Make sure that all screws are

severally tightened. The correct torque to use is 24 Nm. Use a torque

wrench to be sure the screws are correct tightened.

New cutting blades must be used with reduced speed

for the feeding at about 200 cut. When the running-in

has been done the cut can be performed at normal speed.

As a basic rule the blade should never be overheated.

If excessive smoke or heat is generated or if the motor stalls

the cut sequencemust be interrupted immediately and the

cause found.

Lid

Front hatch

Summary of Contents for PowerCut 5-85ot

Page 1: ...PowerCut 5 85ot UseR MAnUAL edition II 2017 09 08 serial number _________________...

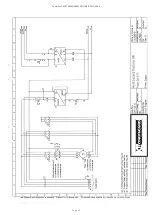

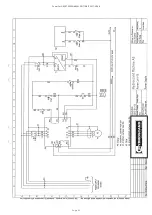

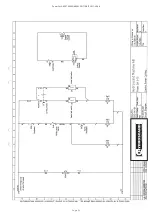

Page 13: ...Page 13 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08 8 1 A1 Wiring diagram Y D starter...

Page 14: ...Page 14 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 15: ...Page 15 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 16: ...Page 16 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 17: ...Page 17 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 18: ...Page 18 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 19: ...Page 19 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 20: ...Page 20 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

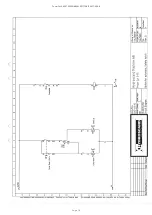

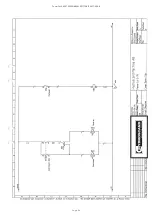

Page 21: ...Page 21 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08 8 2 A2 Wiring diagram Soft starter...

Page 22: ...Page 22 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 23: ...Page 23 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 24: ...Page 24 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 25: ...Page 25 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 26: ...Page 26 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 27: ...Page 27 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...