Page 9

PowerCut 5-85OT USER MANUAL EDITION II 2017-09-08

5. starting up

before plugging in the machine on the electrical net, ensure that the voltage corresponds

to the voltage on the machine. Make sure that air is supplied to the machine and that the

pressure is sufficient. Do ALWAYS use goggles and hearing protections when using the

machine. Keep fingers and other body parts off from areas where the machine is making

linear and circular movements. Do ONLY use the machine to cut hydraulic hoses. When the

machine is intended for cutting other kinds of hoses do ALWAYS contact hydroscand Mach-

ine Ab for consultation in the matter. Ensure that every possible safety precaution is taken

before starting up the machine. Check the cutting blade for possible damages, that it is

securely tightened and that it can rotate freely. Check that the hose bend system is working

properly. When cutting hoses with outer diameters exceeding 2” make sure that the pre-

bend help system is working properly. When the machine has started ensure that the direc-

tion of rotation of the cutting blade is all right. The upper edge of the cutting blade must

rotate towards the back part of the cutting machine. If the machine is

vibrating abnormally, STOP ThE MAChINE IMMEDIATELY and check the reason of the vibra-

tions.

5.1 operator position

The operator must be in such a position that he is ensuring safety and that the cutting is

easliy observed.

5.2 starting up

Release the emergency button by turning it clock-wise. Select your cutting speed.

5.3 Cutting

Press the start button and then press the foot pedal down. You are ready to cut !

Minimum cutting length is 130 mm and the cutting speed is adjusted according to the

actual hose dimension in process.

…hoses of dimension above 2” up to 3”, shall the cutting supports NOT

be used.

note!

Always adjust the cutting speed according to hose dimension in process. this ensures

that the cutting blade lifetime is optimal, that it stays sharp.

Summary of Contents for PowerCut 5-85ot

Page 1: ...PowerCut 5 85ot UseR MAnUAL edition II 2017 09 08 serial number _________________...

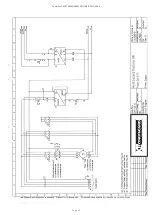

Page 13: ...Page 13 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08 8 1 A1 Wiring diagram Y D starter...

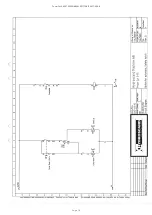

Page 14: ...Page 14 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 15: ...Page 15 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 16: ...Page 16 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 17: ...Page 17 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 18: ...Page 18 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 19: ...Page 19 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 20: ...Page 20 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

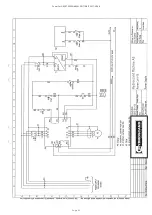

Page 21: ...Page 21 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08 8 2 A2 Wiring diagram Soft starter...

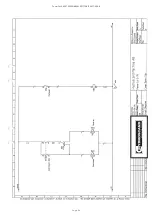

Page 22: ...Page 22 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 23: ...Page 23 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 24: ...Page 24 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 25: ...Page 25 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 26: ...Page 26 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...

Page 27: ...Page 27 PowerCut 5 85OT USER MANUAL EDITION II 2017 09 08...