12

CLEANING, SANITIZING, AND CARTRIDGE REPLACEMENT PROCEDURE

1. Mix a mild cleaning solution of dish soap and clean

potable water in the plastic bowl.

2. Shut feed water supply valve and open product water

faucet to relieve system pressure.

NOTE:

Do not attempt to remove filter housings until water

flow stops. This reduces pressure inside the

system so housings may be safely removed.

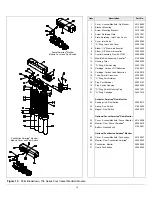

3. Remove each filter housing by turning it counter-

clockwise. Remove each filter cartridge as its housing

is removed. Discard filters.

Icemaker:

Transfer ice cubes from bin/tray to clean

freezer container for storage until procedure is done.

NOTE:

Use sanitary rubber gloves for this procedure to

avoid contaminating sanitizing solution or filters.

Wear gloves whenever cleaning/ sanitizing system

components or handling new filter cartridges.

4. Remove filter housing "O" rings and wash them with

cleaning solution. Rinse them well with clean potable

water. Inspect the "O" rings for damage (i.e., nicks or

scratches). Replace damaged "O" rings.

NOTE:

Use caution when cleaning module. Do not get the

Smartap

®

Flow Monitor electronics, wiring, or

connectors wet.

5. Clean filter housings and manifold ports, inside and

outside with washcloth and cleaning solution. Do not

use abrasive materials.

6. Rinse housings/manifold with clean potable water.

7. Inspect manifold and filter housing "O" ring groove

area for damage (i.e., nicks or scratches). Replace

damaged components.

8. Place a small amount of "O" ring lubricant over the

surface of the filter housing "O" ring. Install the "O" ring

into the filter housing groove.

TO SANITIZE SYSTEM:

Complete Steps 9-29.

TO INSTALL FILTERS:

Complete Steps 17-29.

CAUTION:

WEAR SAFETY GLASSES WHILE

PERFORMING THIS PROCEDURE.

CAUTION:

EXCESSIVE CONCENTRATIONS OF

BLEACH WILL DAMAGE PLASTIC AND

RUBBER COMPONENTS. Rinse all parts

that contact bleach thoroughly with clean

potable

water.

CAUTION:

Read the "WARNINGS" on the bleach

container before using.

CAUTION:

Handle sanitizing solution carefully. Avoid

contact with unprotected areas.

9. Mix sanitizing solution of 1.5 ml (1/3 teaspoon) of

household bleach and 3.8 L (1 gallon) of clean, potable

water in the bucket. Mix the solution well.

10. Add 236 ml (one cup or 8 oz.) of sanitizing solution to

each of the filter housings and install them onto the

manifold (do not install filters at this time). Tighten

each filter housing by hand only.

NOTE:

TIGHTEN FILTER HOUSINGS BY HAND

ONLY. Do not use tools as they will over-

tighten and damage housings.

11. Slowly open the feed water supply valve.

12. Open product water faucet. Keep open for 5 seconds

after water starts coming out.

13. Close the product water faucet.

14. Wait 30 minutes, open product water faucet and let

water flow 5 minutes.

15. After 5 minutes, close feed water supply valve and

allow water to flow until system pressure is relieved.

NOTE:

Do not attempt to remove filter housings until water

flow stops. This reduces pressure inside the

system so housings may be safely removed.

16. Remove the filter housings and dispose of the water.

Rinse housings and manifold ports thoroughly with

clean potable water.

NOTE:

Do not remove protective plastic bag from filters.

Open the top of the bag only enough to expose the

top cap and "O" rings. Place a small amount of

“O” ring lubricant on surface of each “O” ring.

17. Install the filter cartridges. Hold cartridge by its

protective plastic bag and insert the cartridge into the

manifold turning it 1/2 turn as it enters the port (See

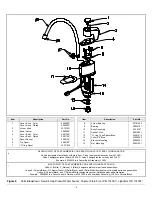

Page II, Figure 1 for location of each cartridge).

Slide bag from cartridge and discard. Replace each

filter housing as each cartridge is installed.

NOTE:

TIGHTEN FILTER HOUSINGS BY HAND

ONLY. Do not use tools as they will over-

tighten and damage housings.