Installation, Programming and Maintenance User Guide Oxymatic Smart

V. 1.3.2. May 2015

18

6.

PREPARATION OF THE WATER TO TREAT (VERY IMPORTANT!)

The steps for the initial treatment of water OXYMATIC ® system before installation are:

6.1.

BALANCED WATER

To carry out proper disinfection of water and ideal for your pool, regardless of system used (chlorine,

bromine, oxygen, peroxide, ozone, etc ...) is necessary for the pool water to be balanced in order to avoid

improper disinfection and corrosion and / or precipitation of metal, limestone, stains of all kinds, cloudy

or green water, etc ... You'll need to check the parameters below:

TDS recommended

≥

600 ppm.

Total Alkalinity: 100-175 ppm.

pH must be between 6.8 and 7.2.x

When water becomes unbalanced corrosive or scale and considerably reduces the oxidizing agent

(Chlorine, Bromine, Oxygen, Peroxide, Ozone, etc ....), And that disinfection is minimal. Water flows

progressively deteriorate makes titanium electrodes and copper, and other metal parts in the circuit of

the water and swimming pool.

In contrast, when the water is fouling, stains and fouling can occur both in the glass of the pool and in

the water pipe circuit and the electrodes. Because this phenomenon may progressively deteriorate

titanium electrodes and copper.

If the water of the swimming pool comes from a well:

Even as drinking water of this type is not as balanced as tap water (city). May contain different

organisms, bacteria, materials or heavy metals. In this case, the water needs an intensive preparation

before OXYMATIC system performance, and that water must be completely free of metals, bacteria, etc..

Electrical conductivity or TDS (total dissolved solids):

The principle of OXYMATIC based on the hydrolysis determines the conductivity of the pool is an

important factor that favors the creation of ions (the higher the electrical conductivity or the amount of

total solids Dissolved in Water, TDS, the better). For proper operation of the system, the TDS should be

above 600 ppm, or what is the same, the electrical conductivity of the water should exceed the 1200 uS

/ cm.

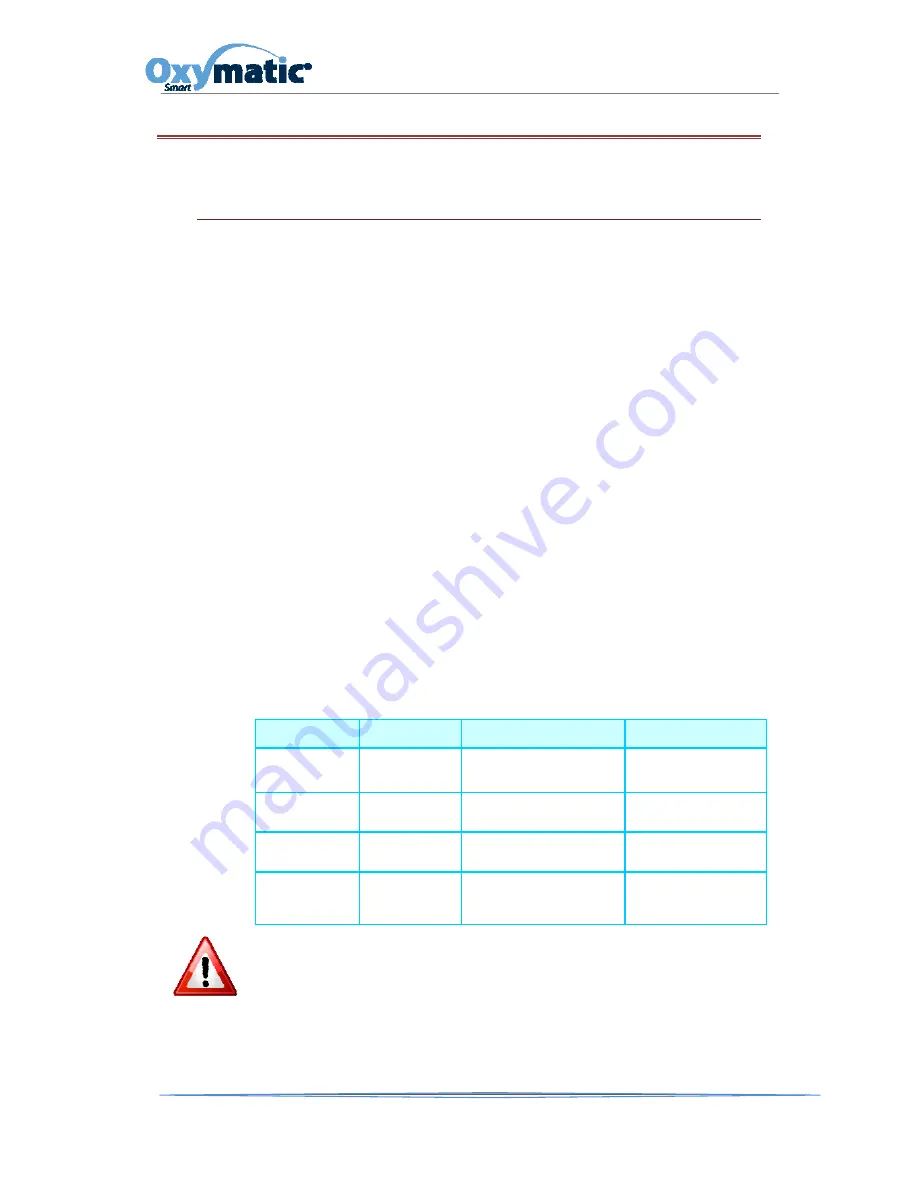

PARAMETERS BOARD OF A POOL

NOTE: When in a given time, have to decrease the pH of the water, we recommend using

sulfuric acid (38%) as pH reducer instead of hydrochloric acid. This is because the hydrochloric

acid also reduces the alkalinity, 2 / 10 while reducing the pH of the water the same amount of

hydrochloric acid. It is also safer than hydrochloric acid and does not emit fumes or gases.

PARAMETER

RECOMMENDED

VALUE

INCREASE

DECREASE

Calcium hardness

(ppm)

300 - 500

Calcium Hardness Increaser

Calcium chloride (CaCl2)

20g/m3 up 15 ppm

¨not necessary¨

Total alkalinity

(ppm)

100 - 175

Alkalinity Increaser

Calcium carbonate (CaCO3):

1kg/50m3 increases 10 ppm.

Alkalinity Reducer

Hydrochloric acid (HCl) or

sodium bisulfite (NaHSO3)

TDS (total

dissolved solids)

(ppm)

+600

Common salt (NaCl): 100 ppm

increase 1.5kg/10m3

¨not necessary¨

pH

6.8 – 7.2

PH Increaser

Carbonate (NaCO3) or sodium

bicarbonate (Na (HCO3) 2)

PH Reducer

Sulfuric acid (H2SO4)

better than hydrochloric

acid (HCl)