A Guide to - Wall Mounting & Fixings

Important note:

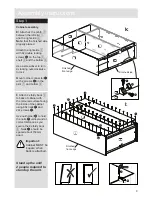

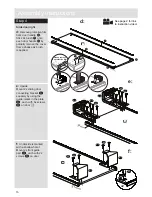

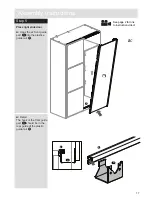

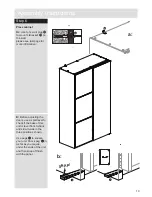

Types of walls

Care &

Maintenance

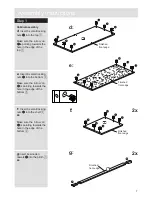

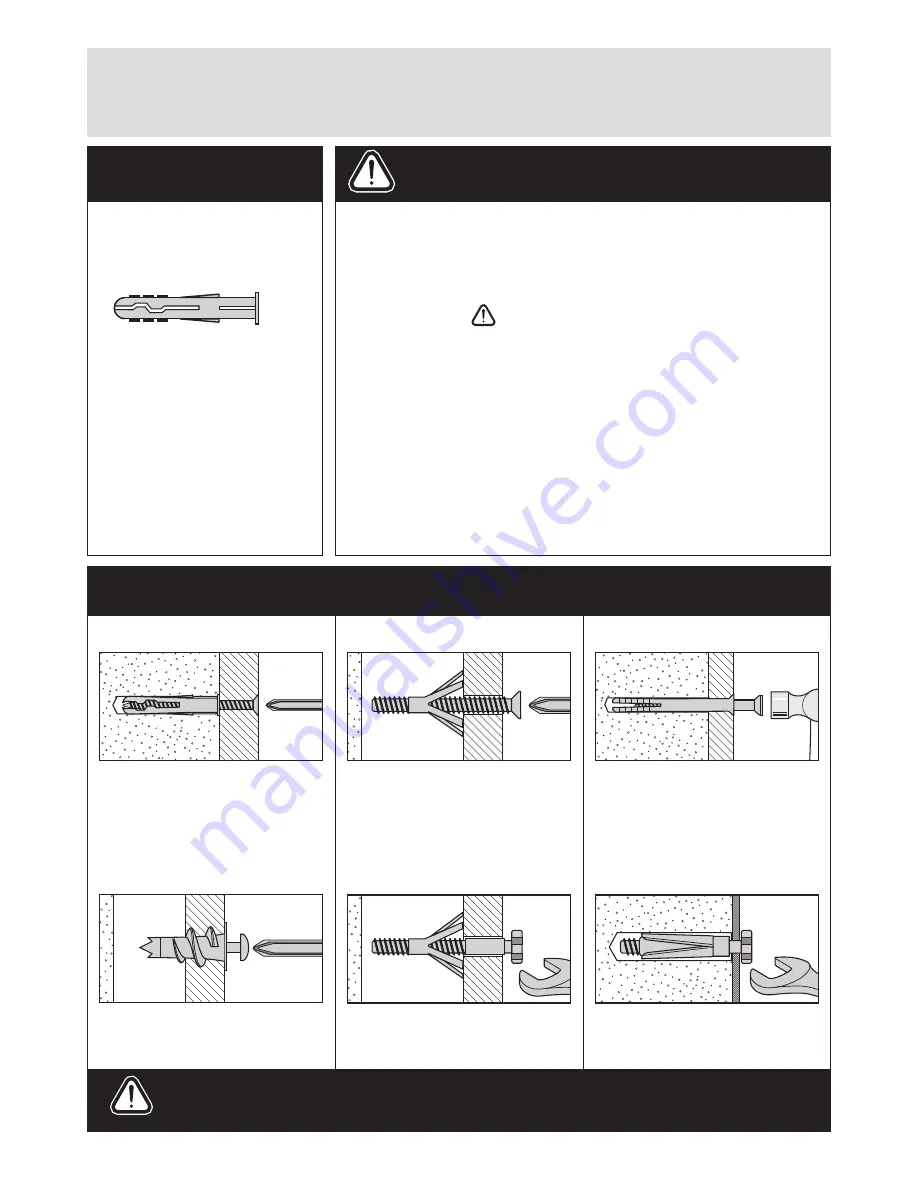

No.1

“General Purpose” wall plug

No.6

“Shield Anchor” wall plug

Heavy loads

No.3

“Cavity Fixing” wall plug

No.4

“Cavity Fixing-Heavy Duty”

wall plug

No.5

“Hammer Fixing” wall plug

No.2

“Plasterboard” wall plug

Generally aerated blocks should not

be used to support heavy loads, use

a specialist fitting in this case. For light

loads, general purpose wall plugs can

be used.

For use with heavier loads such as TV

& HiFi speakers and satelite dishes etc.

For use with plasterboard partitions or

hollow wooden doors.

For use when fitting or supporting

heavy loads such as shelving, wall

cabinets and coat racks.

For use with walls stuck with

plasterboard. The hamemr fixing allows

it to be fixed to the wall rather than the

plasterboard. Always check the fixing

is secure to the retaining wall.

is secure to the retaining wall.

For use when attaching light loads on

to plasterboard partitions.

Safety:

Always check the fitting

and location to ensure your safety

in and around the home.

Fitting: From time to time check

the fitting to ensu

re the wall plugs

or screws do not become loose.

You can use one of the following types of wall plug if your walls are made

of brick, breeze block, concrete, stone or wood.

Important:

When drilling into walls always

check that there are no hidden wires or pipes etc.

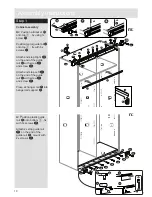

Hints:

1: General rule:

Always use a larger screw and wall plug

if you are not sure.

2:

Ensure you use the recommended drill bit to match the wall

plug and hole size.

3:

Ensure you drill the hole horizontally, do not force the drill or

enlarge the hole.

4:

Take extra care when drilling high walls, ceilings and ceramic

tiles. Ensure wall plugs are inserted beyond the thickness of

the ceramic tiles to avoid the tiles splitting or cracking.

5:

Ensure wall plugs are well fitted and are a tight fit in the

drilled hole.

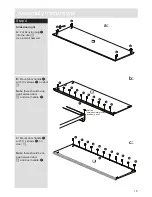

If plastic wall plugs

are supplied with your

product:

Make sure that the screws and wall plugs being used

ar

e suitable for supporting your unit. Consult a qualified

tradesperson if you are unsure.

- these are only suitable for

use in masonry walls.

If you are in any doubt about

the correct wall plugs for

your wall, seek professional

advice.

Failure of the product due to

using incorrect fixings is the

responsibility of the installer.