Page 25

5.5

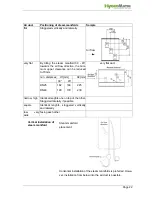

Steam Line

Note:

When installing the steam hose, please pay attention to

the following:

•

The steam hose diameter may not be smaller than the

steam outlet of the HygroMatik steam humidifier (do not

restrict the cross-section, otherwise back pressure will

increase).

•

The steam hose must be without sags and kinks and be

laid with a continuous slope of 5-10% (otherwise sags will

be formed).

•

The steam hose should be as short as possible. In case of

lengths of over 5 m the hose should be insulated to avoid

excess condensation.

•

In the case that steam output is distributed on two steam

manifolds the T-pieces for the steam and condensate hose

should be installed near the manifolds. If the installation is

carried out in this way only one steam hose is necessary

for the main part, loss of condensate will be decreased.

•

Depending on how the hose is laid, hose clips should be

set at intervals of approx. 500 mm.

•

Allow access to the steam hose, so that it can be inspec-

ted later.

•

In case of straight lengths of several meters, it is recom-

mended to place the steam hose in temperature resistant

plastic pipe (40 mm dia for hose DN25; 60 mm dia for hose

DN40) or to use copper pipe.

•

Only genuine HygroMatik hoses are capable of withstan-

ding the operating conditions. Allow for minimum bending

radii:

Steam hose DN 25: Rmin = 200 mm

Steam hose DN 40: Rmin = 400 mm