Page 21

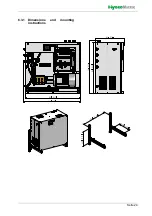

5.2 Mechanical assembly Vortex

wall

This section is for the company in charge of

the duct installations. For the operator of the

nozzle system, the following remarks are for

information only.

The installation of the device and the humidi-

fier chamber may only be carried out by per-

sonnel with appropriate expertise.

HygroMatik accept no liability for damages

resulting from incorrect assembly.

The assembly of the spray system an the

integration of the aerosol separators in the

humidification chamber are described in

detail in the „Installation and initial operation

instructions for HygroMatik adiabatic humidi-

fication systems“ document. Following below

is a line-up of the bullet points for overview

purposes:

•

The guide rails and mounting angle for

the vortex module wall and aerosol

separators can be supplied on-site. The

guide rails must already be installed

before system start-up. Also, the vortex

module wall and aerosol separators

must already be installed

•

The guide rails must be designed in a

way that the vortex module wall and

aerosol separators can be removed (for

servicing)

•

The humidification component should

be built like a scrubber housing with a

decline of at least 1.5° towards the trap

(siphon) and should be waterproof

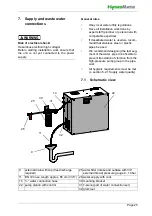

•

The water outlet must feature siphon

and allow for free draining

•

The humidification chamber should be

aerosol-tight and it should be able to

withstand desalinated water.

•

The minimum humification section

length (distance between spray system

and aerosol separators) is 0.9 m. This

corresponds to a total installation

length of 1.5 m (see fig. 2 in the „Instal-

lation and initial operation instructions

for HygroMatik adiabatic humidification

systems“ document). Should this instal-

lation length not be feasable, please

contact HygroMatik

•

Next to the spray system and the drop-

let separators (in direction of the

humidification chamber walls), a mini-

mum distance of 0.5 m to other

installed components must be main-

tained

•

The air flow must be laminar. i.e. in

case of a fan installed upstream of the

spray system, a minimum distance of

1.0 m must be obeyed or other measu-

res must be taken

•

Ensure that after installation the humid-

ification chamber is leakage-free

•

Before initial start-up of the system

check again that the humidification

chamber has been thoroughly cleaned.

In particular the humidification chamber

and the ventilation duct upstream of the

chamber must be free from metal

swarfs to prevent corrosion

Risk of material damage to the vortex

module due to excessive temperature.

The vortex modules must not be exposed to

temperatures >60 °C.

Mounting or insertion of additional equipment

is only permitted with the written consent of

the manufacturer. Otherwise the guarantee

and warranty will become void.

Please note

NOTICE

Please note