Page 71

14. Faults

14.1 Fault Management

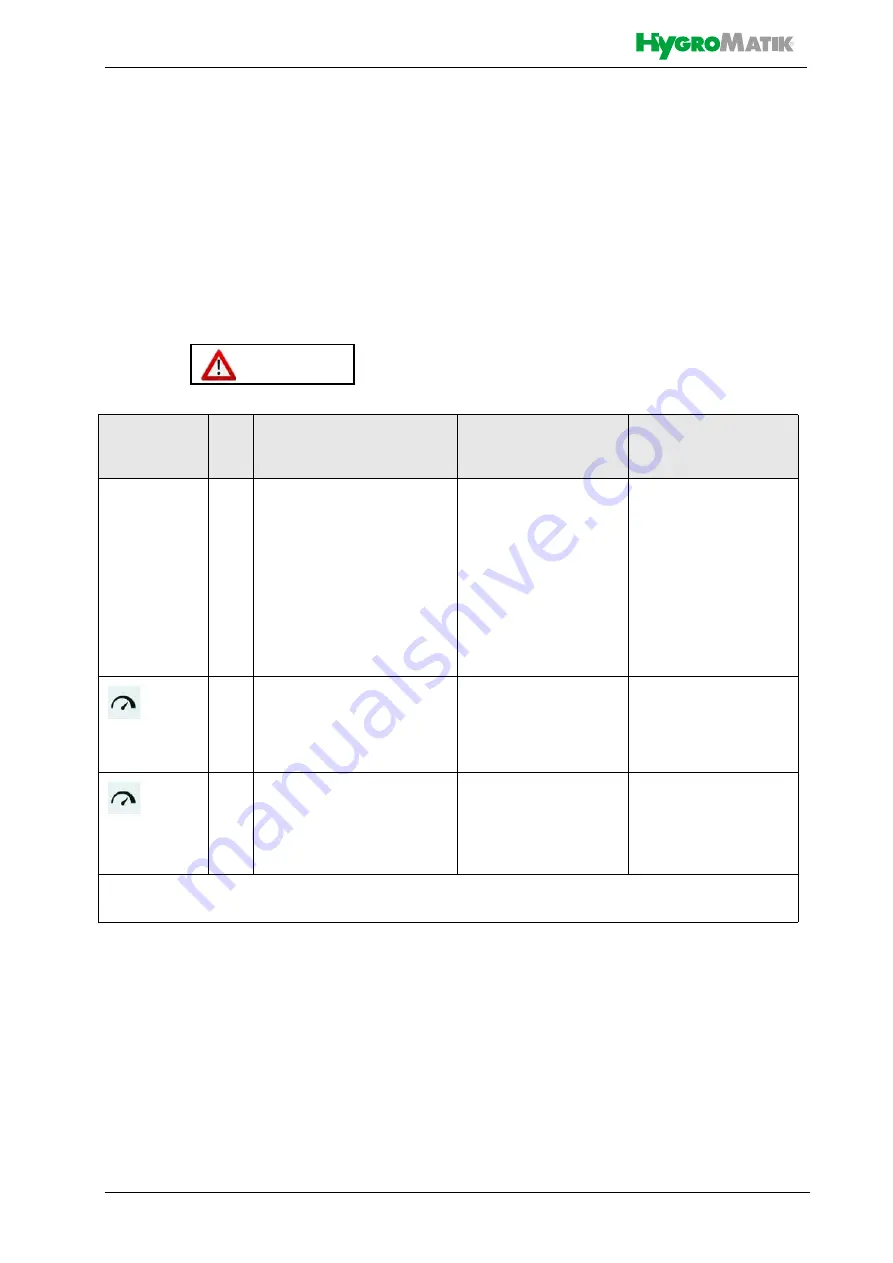

In the event of a fault, the humidification/cool-

ing is haltet. The relevant display field is then

shown instead of the HygroMatik logo. The

display field shows a warning symbol, the

„Fault“ message and - in paranthesis - the

fault code:

When touching the fault message display

field, the unit info screen opens with the fault

message in plain text and information con-

cerning the unit and its current state.

The majority of fault messages is additionally

accompanied by the flashing of one or more

icons, allowing for a first limitation of the

cause of fault.

14.1.1 Table of fault messages, pos-

sible causes and counter-

measures

Fault (001

)

e.g.:

These icons

flash

Fault

Code

Fault message

Possible cause

Counter measure

002

Expansion board

Expansion board not detec-

ted by the sofware

•

p.c.b. connection not

o.k.

•

Check firm connec-

tion of boards

•

p.c.b. not present or

defective

•

Connect board,

replace board if defec-

tive

•

CAN bus addressing

not correct

•

Check DIP switch

settings on extension

board (see fig. in sec-

tion 3.4).

022

*)

Input_current_min

The min. value of the input

signal is no plausibel

•

Sensor, wiring or

signal source defective

•

Check sensor, wiring

and signal source, if

relevant

024

025

*)

Input_resistance_OC

Input_resistance_SC

The resistance measured is

not correct („infinite“ or

„zero“, resp.)

•

Sensor, wiring or

signal source defective

•

Check sensor, wiring

and signal source, if

relevant

•

Input stage defective

•

Replace mainboard

*) When the PI controller is in use, fault codes 022 to 025 relate to the sensor. In case of an external

controller, the signal source is referred to.