Page 12

4. Composition and function of

the HygroMatik high-pres-

sure nozzle system HPS

4.1 Fields of application

Typical application of the high-pressure noz-

zle system is the humidification of an supply

air stream. As an order option, a particular

unit variant is available that is used for

exhaust air cooling. An other order option is

the „Combined system“ that supports both

operation modes. In a combined system, the

actual operation is determined by the termi-

nal wiring that usually encompasses a

switch for mode selection.

4.2 Functioning

The high-pressure nozzle system is based on

atomisation of water.

Desalinated water is fed into a high-pressure

piston pump. With an operating pressure of

up to 75 bar, the water is atomized by means

of high-pressure nozzles. These nozzles

generate a very fine spray mist which is

taken up by the air in the humidification

chamber. The ambient air is cooled adiabati-

cally in the process

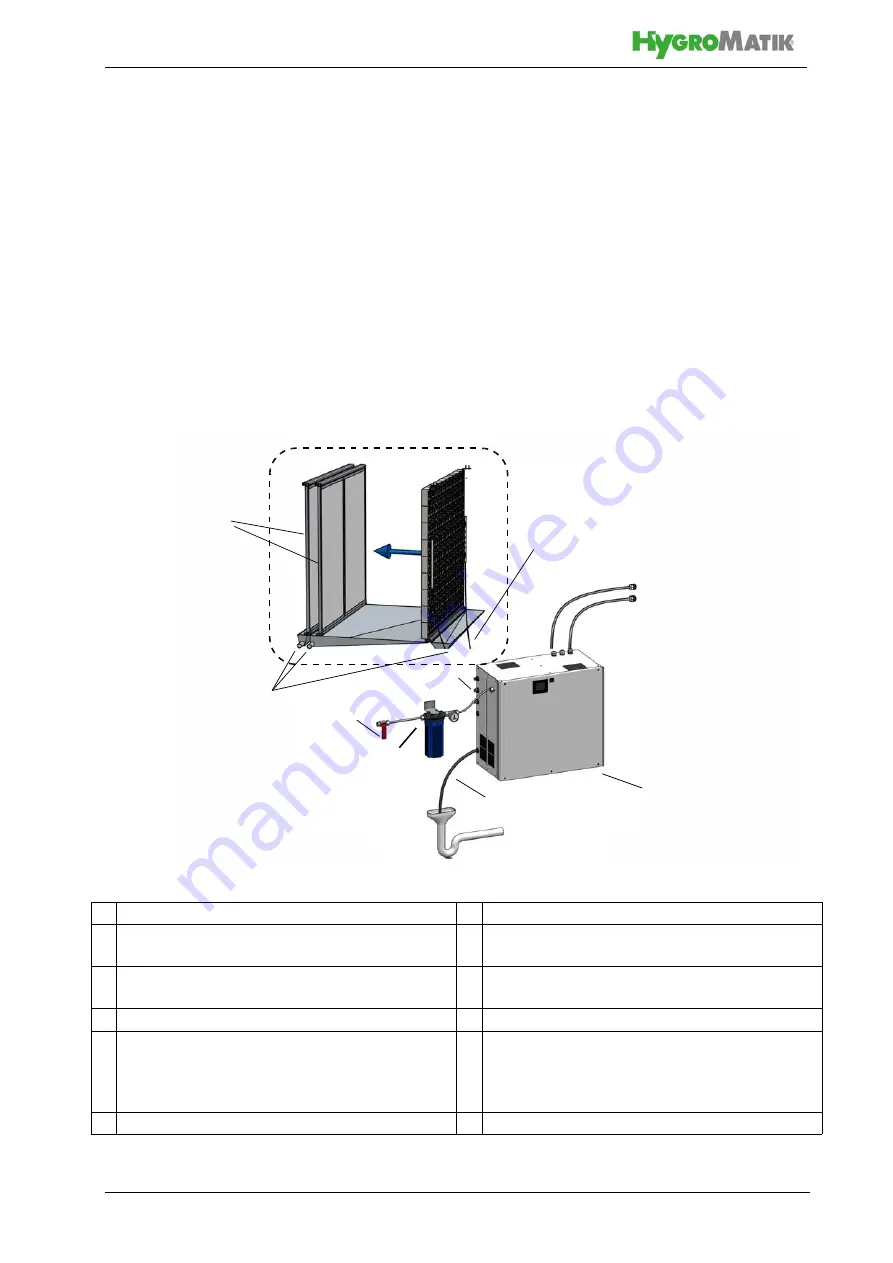

4.3 Schematic diagram of the

system components

4

29

28

21

27

26

25

24

9

20

22

23

9 Electrical connections

25 Water filter with pressure gauge

20 spray system (exemplarily shown with two

nozzle segments)

26 Water supply via cock

21 pressure hoses,

max. length 15 m

(49 ft.)

27 Water drains (siphoned)

22 high-pressure pump group, control

28 aerosol separator (2 step), exemplary

23 1¼ “water drain hose to free running tap

29 Installation in humidification cabin with darke-

ning window (according to VDI 6022) and wa-

ter tray or in a duct with service doors and

water tray

24 water supply connection hose