Page 14

4.4.4 Supply air humidification 4

load mode

The 4-load-configuration allows for exact

humidification controllability even in the

range of minimum output demand.

A prerequisite for this mode of operation is

the availability of 4 independant nozzle sec-

tions. For controlling the supply air humidifi-

cation, an on-site control signal of 0...10 V

(0...20 mA / 0...140

Ω

) is required that is

transformed to an internal actuator signal.

In the range up to approximately 12.5 percent

of the actuator signal (switching point 1), only

one nozzle section is driven with an atomisa-

tion pressure of 25...75 bar, the so called „1

st

load“. Beyond that level,the pumping sta-

tion switches on the second nozzle section

and reduces the pressure to 25 bar. Following

this, with rising humidification demand, up to

approxomately 25% of the actuator signal, the

atomisation pressure is proportionally in-

creased up to the maximum of 75 bar („2

nd

load“).

Beyond this, the third nozzle section is

switched on („3

rd

load“) while the pressure is

decreased to 25 bar again. The further in-

crease of the actuator signal up to approxi-

mately 50%, the atomisation pressure is

proportionally increased to 75 bar.

Beyond the 50 percent, the fourth nozzle

stage is also switched on („4

th

load“) and the

atomisation pressure is reduced again to 25

bar. With the control signal now rising up to

100 percent, the atomisation pressure rises to

75 bar and the system reaches maximum

possible humidification output.

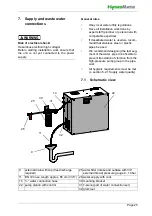

4.4.5 Exhaust air cooling

The high-pressure nozzle system was either

ordered as an exhaust cooling system or can

be put to exhaust air cooling operation mode

by (switched) wiring, when a combined sy-

stem was ordered (s. section 4.4.6). As a

control signal, the whole variety is available

that is possible for the control supply air humi-

dification mode. In contrast to the supply air

humidification mode, exhaust air cooling com-

prises no load swiching.

The purpose of the extract air cooling is to

transfer maximum cooling capability into the

supply air flow (heat exchanger provided by

customer), to support air conditioning

systems. In this type of application

humidification is typically 95 to 100 percent.

All nozzles are immediately supplied with

maximum power when the system is enabled.

If the humidity switch or another sensor

detects that cooling is no longer necessary

the enabling is cancelled and the system goes

to stand-by mode.

4.4.6 Combined system

A combined system allows for switching bet-

ween supply air humidification and exhaust

air cooling. Supply air humidification can be

run in the „Standard“, „2-load“ and „3-load“

modes with the full variety of control signals

that are supported by a dedicated system.

When exhaust air cooling is selected, how-

ever, only 1-step operation is possible.