Page 18

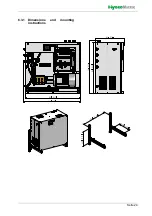

4.5.3 Vortex modules

The vortex modules provide for effective mix-

ing of the air and water mist.

Due to their special design, they generate

turbulence and shear zones which lead to a

homogeneous distribution of aerosols along

the humidification section (min. 0.9 m).

The vortex modules (dimensions: 150 x 150

mm) are delivered individually and can be

assembled to form a wall. For optimal moisture

absorption, the air velocity is 0.9...2.8 m/s. The

vortex module wall exhibits a low pressure drop

of 80 Pa at an air velocity of 2.0 m/s.

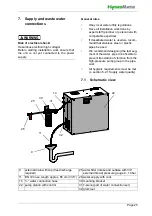

4.5.3.1 Atomising nozzles for vortex

modules

Desalinated water at a pressure of 25 to75

bar reaches the high-pressure nozzles where

the water is atomised to form ultra-fine mist-

like aerosols. The aerosols enter the area of

the vortexed air stream downstream of the

vortex modules. The air and aerosols are

mixed intensively here.

Two different types of atomising nozzles are

used: atomising nozzles with a spray angle of

120° for general application and those for the

edge areas of the vortex module wall featu-

ring a spray angle of 60°.

Functioning:

Water is forced with high velocity into circu-

lation by the swirl insert of the nozzle.

Thereby the required atomisation of water

into extremely fine aerosols takes place at

the outlet opening.

The high operating pressure of the water (up

to 75 bar) is nearly completely translated into

the exit velocity from the nozzle. The higher

the operating pressure the finer the droplets.

Material of the high-pressure nozzle:

St.

1.4404

Spray characteristics operating pressure

of 75 bar

•

Volumetric flow rate: 7,1 l/h *)

•

High percentage of droplet distribution

in the range of 6-35 µm

*) Information is subject to change or altera-

tion without prior notice

Vortex module

Vortex modul wall

1

2

1 - nozzle body 2 - nozzle opening